Minimac Systems Ensures Optimal Lubrication for India’s Largest Indigenous Aircraft Carrier

Executive Summary

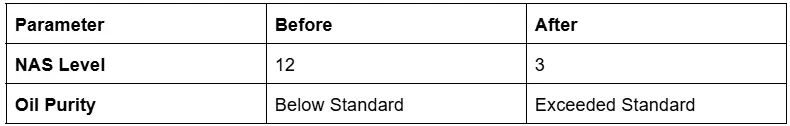

Minimac Systems successfully executed a critical pre-commissioning lubrication project for India’s largest Indigenous Aircraft Carrier (IAC). The objective was to flush and filter the gearbox and standby piping lubrication systems, ensuring optimal NAS cleanliness levels. By deploying advanced filtration systems, Minimac reduced NAS levels from 12 to 3, exceeding the client's requirements and significantly enhancing the carrier’s operational efficiency and equipment lifespan.

Introduction

Client Profile:

- Industry: Defence

- Client:Indian Navy

- Project: Pre-commissioning flushing of gearbox and standby piping lubrication systems for IAC

- Lubricant Involved: Lube Oil

- Contract Type:One-Time Contract

As part of the Indian Navy’s pre-commissioning requirements, achieving optimal lubrication cleanliness was critical to ensuring the carrier's smooth operation and long-term reliability.

The Challenge

Problem Statement:

Pre-commissioning flushing of lube oil lines is essential to eliminate contaminants such as dirt, welding slag, and debris. The presence of these contaminants could lead to premature wear and tear, impacting system reliability and longevity. The NAS (National Aerospace Standard) level before flushing was measured at NAS 12, far exceeding the acceptable level of NAS 6 or below.

Impact of the Problem:

- Operational Risk:Contaminants in the oil could lead to increased friction, clogging, and system inefficiencies.

- Equipment Damage: Failure to meet NAS standards could result in premature wear of critical components.

- Performance Degradation: Unclean oil could affect overall vessel performance and maintenance cycles.

The Solution

Implementation of Minimac Systems:

To achieve optimal cleanliness, Minimac Systems implemented a two-stage oil filtration and flushing approach:

Stage 1 (Hanger Deck):

- Equipment Used: FS-150 and FS-225 Filtration Systems (150 LPM and 225 LPM capacity)

- Objective:Flush long inlet distances (15 meters from the oil tank) and remove initial contaminants.

- Outcome:Achieved the target NAS cleanliness level for the gearbox and standby piping systems.

Stage 2 (Engine Floor - 9 Decks Down):

- Customized Setup:Booster pump, strainer, and filter arrangement built on-site.

- Objective:Flush the lube oil tanks and purify the oil to meet stringent NAS standards.

- Outcome:Achieved a NAS level of 3, exceeding the client’s requirement of NAS 6.

Features Utilized

- High-capacity oil filtration for deep system flushing.

- Multi-stage contamination removal process.

- Customized on-site setup to accommodate spatial constraints.

Results

Quantitative Outcomes:

Qualitative Outcomes:

- Exceeded NAS cleanliness targets, ensuring superior lubrication reliability.

- Reduced risk of premature wear, prolonging equipment lifespan.

- Enhanced operational efficiency for India’s most advanced naval vessel.

Environmental Impact

- Oil Conservation: Proper flushing prevented premature oil degradation and replacement, reducing waste oil generation.

- Reduced Maintenance Needs: Cleaner systems resulted in lower energy consumption for maintenance activities.

Conclusion

Summary of Benefits

Minimac Systems played a vital role in the successful commissioning of India’s largest aircraft carrier. By ensuring optimal NAS cleanliness levels through advanced oil filtration and flushing, the project significantly enhanced operational efficiency, extended equipment life, and contributed to the carrier’s long-term reliability.

Why Minimac Was Chosen

- Proven Expertise: Successfully executed a critical lubrication project in a high-stakes defence environment.

- Cost Savings: Prevent potential damage to critical naval assets, reducing maintenance and replacement costs.

- Operational Reliability: Ensured seamless pre-commissioning, setting a new benchmark in oil filtration for defence applications.

If your organization faces lubrication challenges in mission-critical applications,

Facing similar contamination challenges at your plant?

Explore our Advanced oil purification solutions.