Minimac Systems Restores Oil Purity at Key Power Facility in Madhya Pradesh, Preventing Costly Downtime

Executive Summary

Minimac Systems successfully deployed advanced oil purification technologies at a leading thermal power plant in Madhya Pradesh. Faced with rising contamination in hydraulic oil across the CHP tank, fan area tank, and mill area oil tank, the plant risked severe equipment damage, unscheduled maintenance, and potential operational shutdowns. Through a strategic combination of FS-series Filtration Systems and LVDH-series Low Vacuum Dehydration Systems, Minimac Systems restored oil purity, safeguarded critical equipment, and ensured uninterrupted power generation.

Introduction

Client Profile:

- Industry: Power Generation

- Location:Madhya Pradesh, India

- Facility Type: Thermal Power Plant

- Oil Type: Hydraulic Oil

- Critical Systems:CHP tank, fan area tank, mill area oil tank

The client operates one of the most crucial thermal power plants in the region, contributing significantly to the state’s power supply. Ensuring the reliability of its lubrication systems is paramount to maintaining consistent power generation.

The Challenge

Problem Statement:

The power plant experienced severe contamination in its hydraulic oil across multiple tanks.

- Rising Moisture Levels accelerated corrosion risks.

- High Mechanical Impurity (MI) levels increased wear and tear on equipment.

- Contaminated oil threatened valves, pumps, and hydraulic machinery, directly increasing the risk of equipment failure and costly unscheduled downtime.

Impact of the Problem:

- Operational Risk:Premature wear, clogged pipelines, and potential equipment failure.

- Financial Losses: Unplanned downtime would disrupt power generation, causing revenue loss.

- Asset Damage: Contaminated oil could permanently damage sensitive hydraulic components, increasing maintenance and replacement costs.

The Solution

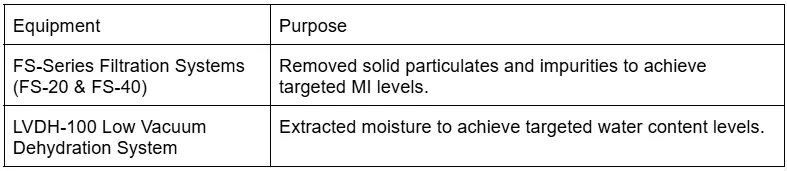

Implementation of Minimac Systems:

Minimac Systems devised a two-pronged approach to restore oil cleanliness and ensure long-term reliability:

Key Features Utilized

- Advanced multi-stage filtration for precision contaminant removal.

- Low vacuum dehydration for rapid moisture reduction.

- Continuous Monitoring: Real-time NAS and moisture tracking to meet client targets.

Results

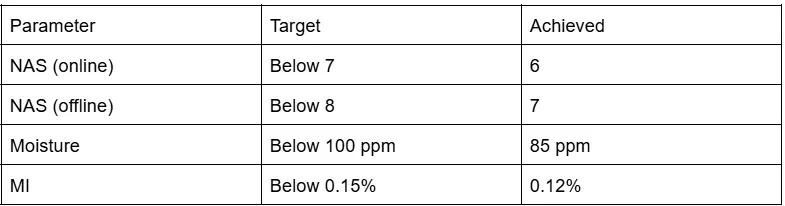

Quantitative Outcomes:

Qualitative Outcomes:

- Achieved and maintained oil cleanliness within target limits.

- Prevented corrosion and abrasive wear, protecting sensitive equipment.

- Minimized risk of unscheduled downtime, ensuring stable operations.

- Enhanced overall equipment lifespan and operational reliability.

Financial & Operational Benefits

- Downtime Prevention: Avoided potential unscheduled shutdowns, saving the client from massive revenue losses.

- Asset Protection: Extended the lifecycle of critical hydraulic equipment and pipelines.

- Cost Savings: Eliminated the need for premature oil replacement and reduced long-term maintenance expenses.

Conclusion

Summary of Benefits

Minimac Systems’ expertise in oil purification played a vital role in enhancing operational reliability at this key power facility. By combining FS-series Filtration Systems and LVDH-series Dehydration Systems, we ensured cleaner oil, better equipment protection, and lower maintenance costs—all contributing to uninterrupted power generation.

Why Minimac Systems?

- Proven track record in critical contamination control for power plants.

- Cost-effective solutions that save crores in potential losses.

- Advanced technology ensures sustainable, long-term reliability.

- A trusted partner with an ongoing Annual Maintenance Contract (AMC) for continuous support.

Facing similar contamination challenges at your plant?

Contact Minimac Systems today to ensure cleaner oil, reliable equipment, and uninterrupted operations. Explore Oil Purification Solutions