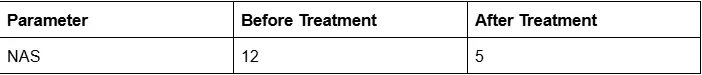

Minimac Systems Lowers NAS from 12 to 5 at Chhattisgarh FGD Unit.

Executive Summary

Minimac Systems successfully deployed its advanced filtration solution to address severe contamination in the Flue Gas Desulfurization (FGD) unit pipelines in Chhattisgarh. The intervention resulted in a significant reduction of contamination levels, lowering the NAS value from 12 to 5, and ensuring enhanced operational efficiency and environmental compliance.

Introduction

Client Profile:

- Sector:Power Generation

- Location:Chhattisgarh, India

- Lubricant Involved: FGD System Oil

- Problem Type: Severe Solid Contamination and elevated NAS value

- Solution Type:Filtration System

The power plant integrates Flue Gas Desulfurization (FGD) technology to minimize sulfur dioxide (SO2) emissions, enhancing environmental sustainability.

The Challenge

Problem Statement:

The newly installed FGD unit and its connected pipelines were severely contaminated due to mechanical operations. This contamination posed major operational and environmental risks:

- Worst Case Scenario: Potential failure of the FGD unit due to high contamination levels.

- Monetary Loss: Estimated losses in crores of rupees.

- Non-Monetary Losses: Increased downtime, productivity loss, and compromised environmental compliance.

Impact of the Problem:

- High contamination levels threatened the efficiency and longevity of the FGD system.

- Delayed commissioning of the unit could have led to regulatory challenges.

- Increased operational risks and maintenance costs.

The Solution

Implementation of Minimac Systems:

To address the contamination issue, Minimac Systems deployed advanced filtration technology within a limited timeframe of 15 days. The team efficiently arranged the required machinery, fittings, and hose pipes to ensure swift execution.

Features Utilized

- FS 150: Engineered to tackle even the most challenging contamination issues in industrial fluids. With its advanced multi-stage filtration technology, it efficiently removes particulates, water, and sludge, ensuring optimal fluid cleanliness.

- Customized Manifolds & Hose Pipes:Ensured seamless integration with the existing pipeline system.

- Rapid Deployment Strategy: Executed within two days to meet the client’s urgent operational timeline.

Results

Quantitative Outcomes:

- Complete purification of FGD unit pipelines within 15 days.

- Prevention of potential financial losses and operational disruptions.

Qualitative Outcomes:

- Enhanced Machinery Safety: The filtration process ensured the longevity of critical equipment.

- Smoother Operations:Improved system efficiency and reduced downtime.

- Environmental Protection:The process significantly reduced emissions, contributing to sustainability goals.

Conclusion

Summary of Benefits

Minimac Systems’ rapid response and advanced filtration solutions successfully mitigated contamination issues in the Chhattisgarh FGD unit, preventing potential financial and operational losses. The intervention not only enhanced system efficiency but also supported environmental compliance.

If your industrial facility faces similar contamination challenges, contact Minimac Systems today to discover how our advanced filtration solutions can enhance your equipment’s reliability and efficiency.

Learn More About Oil Filtration Systems Solution.