EH Oil Reconditioning for Turbine Reliability in Power Plant

Executive Summary

A 1,320 MW (2 x 660 MW) supercritical coal-fired power plant in northern India was struggling with a rapid TAN value increase and high moisture content in its Electro-Hydraulic Control System (EHC) or the Digital Electro-Hydraulic System (DEH) oil. Their existing oil regeneration system failed to control these issues, risking unplanned turbine shutdowns.

To solve this, Minimac Systems implemented its MLC LVDH TRIX-20 Electro-Hydraulic (EH) Oil Reconditioning System, a comprehensive solution designed to eliminate solid contaminants and moisture and reduce TAN effectively. preventing potential daily losses of ₹1.4 Cr by improving oil health and turbine reliability.

Key Metrics:

- TAN Reduced: Ion exchange lowered acid levels, restoring EH oil health.

- NAS 5 Achieved: 3-micron filtration removed fine contaminants.

- ₹1.5 Crore Saved:Avoided turbine shutdowns and downtime losses.

- Turbine Reliability Improved:Stopped servo valve hunting in DEH system.

Introduction

Minimac Systems specializes in oil purification, fluid reconditioning, and contamination control solutions for critical industrial applications. The MLC LVDH TRIX 20 is an advanced EH oil reconditioning system designed to remove contaminants, control moisture, and extend oil life.

Client Profile:

- Industry: Power Generation

- Plant Capacity:1,320 MW (2 x 660 MW)

- Location: Northern India

- Technology Used: Indo-Chinese Electro-Hydraulic Control System (EHC) System

The Challenge

Problem Statement: The power plant faced rapid TAN value escalation and excessive moisture contamination in its turbine governing system's EH oil. Their existing EHGC tank regeneration system failed to control the oil degradation, leading to:

- Increased risk of servo valve failure

- Unstable turbine operation (hunting issues)

- Reduced power generation efficiency

- Risk of unplanned shutdowns, causing significant financial losses

Impact of the Problem:

Without intervention, the plant would have faced frequent oil replacements, potential turbine damage, and severe downtime costs of ₹1.4 Cr per day.

The Solution

Implementation of Minimac Systems:

Minimac Systems provided a customized Electro-Hydraulic (EH) oil reconditioning solution by installing MLC LVDH TRIX 20. The system was deployed at both turbine units to actively recondition the oil and maintain optimal performance.

Features Utilized:

- Superfine Filtration:Eliminated solid contaminants to improve oil cleanliness.

- Vacuum Dehydration Technology:Removed excess moisture to prevent oxidation and sludge.

- Ion Exchange Technique: Reduced Total Acid Number (TAN), prolonging oil life.

- Inert Gas Blanketing:Prevented further moisture ingress and stabilized system performance.

Additionally, Minimac’s service engineers trained the plant’s team on contamination control, Electro-Hydraulic (EH) oil maintenance, and best practices for extending oil life.

Results

Quantitative Outcomes:

- ₹78 Lakh savedby eliminating unnecessary oil replacements.

- ₹5.6 Cr saved in potential downtime costs.

- 14,400 kg CO2 reduction,supporting sustainable power generation.

Alongside the installation, Minimac’s service engineer provided training on FRF maintenance, contamination control, and the importance of oil analysis programs.

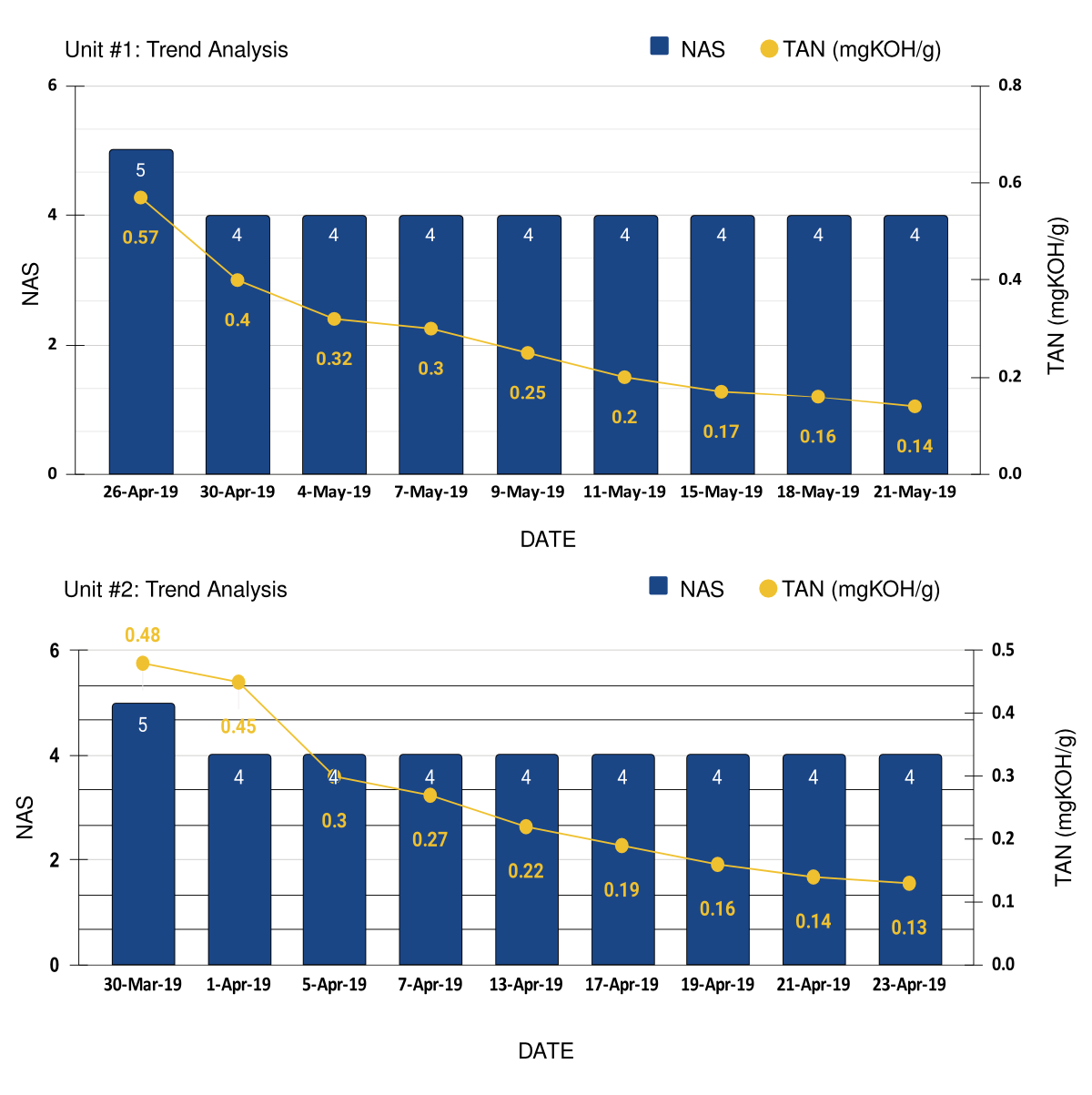

The above graph shows the trend analysis of NAS 1638, Moisture, and TAN value during the one-month installation of the reconditioning of EH oil at the customer site.

Qualitative Outcomes:

Client Feedback:“Minimac’s Electro-Hydraulic (EH) oil reconditioning system prevented a major crisis at our plant. It not only stabilized our turbine operation but also provided significant cost savings. Their training program was valuable for our team.”

Conclusion

Minimac Systems' Electro-Hydraulic (EH) oil reconditioning solution significantly improved turbine reliability, prevented unplanned shutdowns, and eliminated unnecessary oil replacement costs. By reducing contamination, moisture, and acid formation in the oil, the system helped extend the fluid’s life, ensuring optimal turbine performance. Additionally, the reduction in CO2 emissions contributed to a more sustainable operation. The success of this project highlights the effectiveness of proactive oil maintenance in preventing critical failures and financial losses. With Minimac Systems, industries can enhance equipment efficiency, reduce maintenance costs, and achieve long-term operational stability

Discover more about our oil purification systems by Clicking Here