EH Oil Recondition System | Reduce TAN & Turbine Reliability

Executive Summary

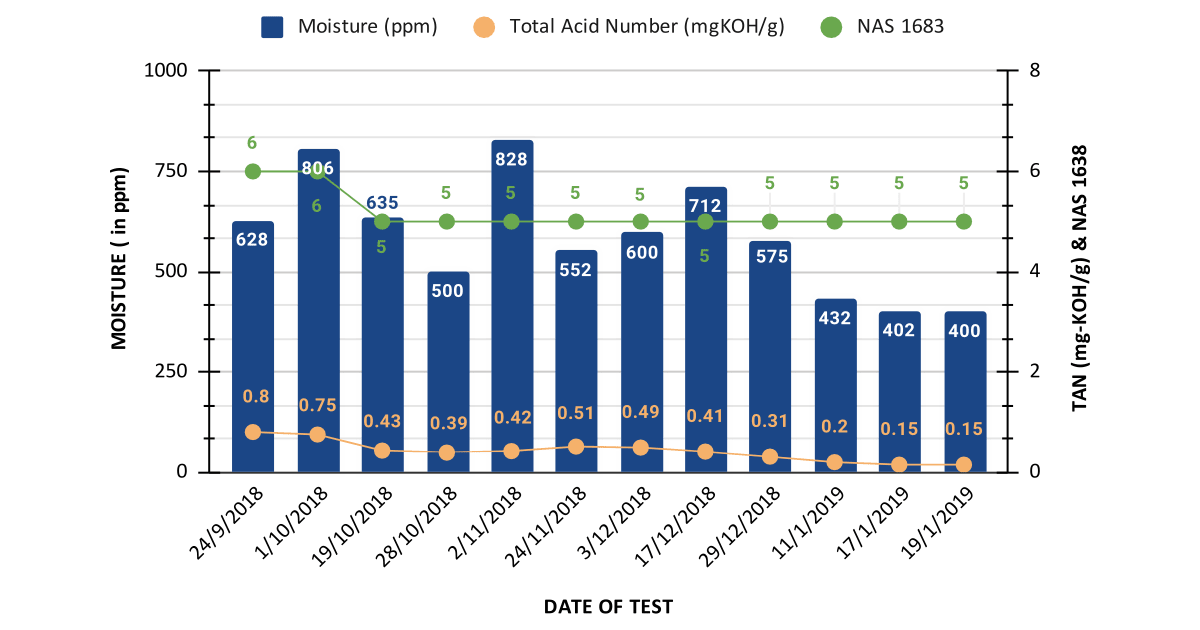

A 1200 MW coal-fired thermal power plant in southern India was facing critical EH oil degradation in its Electro-Hydraulic Control System (EHC) or the Digital Electro-Hydraulic System (DEH). Rising Total Acid Number (TAN) and excessive moisture contamination threatened turbine reliability and efficiency.

Minimac Systems' Electro-Hydraulic EH oil reconditioning solution, MLC LVDH TRIX 20, restored oil quality, prevented an unplanned turbine shutdown worth ₹1.05 Cr per day, and saved ₹4.8 Cr in costs.

Key Metrics:

- Reduced Total Acid Number (TAN): Achieved significant reduction through Ion Exchange Purification, restoring EH oil quality.

- Achieved NAS 5 Cleanliness: Using superfine filtration (3-micron filter) to eliminate solid contaminants.

- ₹4.2 Crores Saved:By preventing unplanned turbine shutdowns and extending oil service life.

- Increased Turbine Reliability: Eliminated servo valve hunting and sluggish response in the DEH system.

- Extended EH Oil Life:Reduced replacement frequency with moisture removal and contamination control

Introduction

Minimac Systems is a leader in oil purification and fluid management solutions, specializing in extending oil life, reducing maintenance costs, and ensuring equipment reliability in critical industries.

Client Profile:

- Industry: Power Generation

- Plant Capacity:1200 MW Coal-Fired Thermal Power Plant.

- Location: Southern India.

- System: Indo-Chinese Electro-Hydraulic Control (EHC) system for turbine operation.

The Challenge

Problem Statement: The plant was struggling with:

- A rapid increase in Total Acid Number (TAN)accelerating EH oil degradation

- Excess moisture content,exceeding permissible limits

- Solid contamination, leading to potential servo valve failure and turbine hunting

- High risk of unplanned shutdowns, affecting power generation efficiency

Impact of the Problem:

- Increased risk of turbine failure, causing extended downtimes

- Potential financial losses of ₹1.05 Cr per day due to unexpected shutdowns

- Decreased efficiency and reliability of the EH control system

The Solution

Implementation of Minimac Systems:

Minimac Systems deployed its Electro-Hydraulic (EH) oil reconditioning system, MLC LVDH TRIX 20, engineered with four advanced purification technologies:

Features Utilized:

- Superfine Filtration:Achieved NAS 5 oil cleanliness by removing solid contaminants.

- Vacuum Dehydration Technology:Eliminated moisture contamination to restore oil integrity.

- Ion Exchange Technique: Reduced TAN levels, extending EH oil life.

- Inert Gas Blanketing:Prevented moisture ingress, ensuring long-term oil stability.

Consumables Used

- Filter (10-microns): 1 qty

- Filter (3-microns):1 qty (for NAS 5 cleanliness)

- Total Resin:60 liters

In addition, Minimac’s expert engineers trained the client’s team on proper EH oil maintenance, contamination control, and the importance of an oil analysis program.

Results

Quantitative Outcomes:

- ₹60 Lakh savedby avoiding EH oil replacement.

- ₹4.2 Cr saved by preventing unplanned turbine downtime.

- 14,400 kg CO2 reduction,contributing to sustainability goals.

Qualitative Outcomes:

- Extended EH oil life, reducing frequent replacements.

- Eliminated turbine hunting risks, ensuring smooth operations.

- Improved plant efficiency and reliability, enhancing productivity.

- Client satisfaction: The plant’s maintenance team reported significant improvements in oil performance and turbine stability.

Conclusion

The EH oil reconditioning solution by Minimac prevented oil degradation, reduced TAN levels, and restored turbine reliability. With substantial cost savings and CO2 reductions, this solution highlights the importance of proactive EH oil maintenance in power plants.

Discover more about our oil purification systems by Clicking Here