Minimac Systems Restores Oil Purity at Uttar Pradesh, Preventing Shutdowns Worth INR 10+ Crores.

Executive Summary

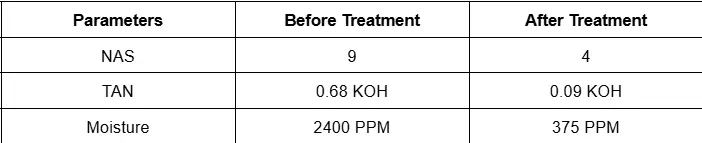

Minimac Systems successfully implemented an advanced oil purification solution at Uttar Pradesh, to address high levels of Total Acid Number (TAN), NAS (National Aerospace Standard), and moisture contamination in FRF oil. This intervention significantly reduced contamination levels, preventing potential shutdowns and saving crores in potential losses.

Introduction

Client Profile:

- Industry: Power Generation

- Location:Uttar Pradesh, India

- Facility Type: Thermal Power Plant

- Oil Type: FRF Oil

- Oil Quantity:FRF oil in Units 1, 2, and 4

The largest thermal power generation plant in Uttar Pradesh operates with a capacity of 3000 MW, comprising six 500 MW units. The plant plays a crucial role in India's energy sector.

The Challenge

Problem Statement:

Uttar Pradesh site faced a severe contamination issue in the FRF oil of units 1, 2, and 4. Elevated levels of TAN, NAS, and moisture posed a significant risk to machinery and the turbine governing system, leading to potential failures and operational shutdowns.

Impact of the Problem:

- Operational Risk:Clogged pipelines and potential failure of valves, machinery, and the turbine governing system.

- Financial Losses: A plant shutdown could cost approximately ₹1.5 crores per minute.

- Asset Damage: Contaminated FRF oil could cause extensive damage to pipelines, valves, and machinery, resulting in crores of rupees in asset loss.

- Non-Monetary Losses: Reduced productivity, unplanned downtime, and decreased operational efficiency.

The Solution

Implementation of Minimac Systems:

To combat the critical contamination issue, Minimac Systems deployed a comprehensive oil purification system, installing:

- LVDH - 100 LPM

- Nitrogen Dehydrator - 20 LPM

- Resin Skid - 20 LPM

- Filtration System (F.S.) - 150 LPM

These advanced technologies worked in tandem to remove moisture, reduce acidity, and lower contamination levels within the FRF oil while ensuring uninterrupted plant operations.

Features Utilized

- State-of-the-art oil purification technology.

- Multi-stage filtration system to eliminate contaminants.

- Rapid moisture removal to prevent corrosion and breakdowns.

- Continuous monitoring to achieve and maintain optimal oil quality.

Results

Quantitative Outcomes:

Within three days of operation, moisture levels showed a significant decline, with complete stabilization achieved by the end of the project.

Qualitative Outcomes:

- Avoided potential shutdown costs of ₹1.5 crores per minute, saving crores in lost revenue.

- Eliminated oil replacement costs of approximately ₹10 crores, reducing expenses to just a few lakhs.

- Extended the life of machinery and pipelines, reducing future maintenance and replacement costs.

Conclusion

Summary of Benefits

Minimac Systems' advanced oil purification technology played a crucial role in mitigating the risk of equipment failure at Uttar Pradesh. By significantly reducing TAN, NAS, and moisture levels, the solution ensured continued operations, protected critical assets, and provided immense cost savings.

Why Minimac Was Chosen?

- Cost Savings: Prevented potential oil replacement costs of ₹10 crores, reducing expenses to just a few lakhs.

- Operational Reliability: Minimized downtime and ensured uninterrupted power generation.

- Environmental Benefits: Reduced carbon emissions and enhanced sustainability.

- Client Trust: Quick and effective results reinforced Minimac’s reputation as a trusted industry leader.

If your power plant or industrial facility faces similar contamination challenges, contact Minimac Systems today. Our advanced solutions ensure superior oil quality, enhanced equipment reliability, and significant cost savings.

Learn More About Oil Purification Systems Solutions.