Minimac Saved Millions in Power Plant with EH Oil Filtration

Executive Summary

A 2x600 MW power plant in Northern India faced rising Total Acid Number (TAN) values and moisture contamination in their turbine Electro-Hydraulic Control System ( EHC ) or the Digital Electro-Hydraulic System (DEH) oil. This issue threatened unplanned shutdowns and costly oil replacement. By implementing Minimac Systems' MLC LVDH TRIX-20 Electro-Hydraulic EH Oil Filtration System, the plant effectively reduced TAN levels, eliminated moisture, and extended oil life, resulting in cost savings of approximately ₹1.5 Crore.

Key Metrics:

- TAN Reduced:Restored oil quality using ion exchange purification.

- NAS 5 Achieved: Ultra-clean oil with 3-micron filtration.

- ₹1.5 Crore Saved:Avoided shutdowns and oil replacement costs.

- Turbine Reliability Improved:Eliminated hunting and sluggishness.

Introduction

Minimac Systems is a leader in oil filtration and reconditioning solutions, specializing in technologies that enhance oil reliability and extend equipment life. The MLC LVDH TRIX-20 EH Oil Filtration System is designed to reduce TAN, remove moisture, and eliminate contaminants to ensure optimal performance of turbine Electro-Hydraulic Control System ( EHC ) systems.

Client Profile:

- Industry: Power Generation

- Plant Capacity:2 x 600 MW

- Location: Northern India

- Technology Used: Indo-Japanese Technology Turbine Electro-Hydraulic Control System (EHC) System.

The Challenge

Problem Statement: The power plant was experiencing rapidly increasing TAN values and excessive moisture contamination in the Electro-Hydraulic (EH) oil of their turbine governing system. This degradation was primarily caused by contaminant ingress, moisture ingress, and by-product formation.

Impact of the Problem:

- Electrokinetic Erosion: High TAN values were corroding lines and accessories of the Electro-Hydraulic Control System (EHC).

- Servo Valve Failure & Hunting:Varnish and silt accumulation led to clearance issues, causing turbine sluggishness.

- Unplanned Shutdowns: Risk of generation loss estimated at ₹1.05 Crore per day (15 hours of downtime).

- Costly Oil Replacement:The estimated cost of replacing 1200 liters of EH oil was ₹44 Lakh.

The Solution

Implementation of Minimac Systems:

The power plant installed Minimac Systems’ MLC LVDH TRIX-20 Electro-Hydraulic (EH) Oil Filtration System, designed to address the contamination issues comprehensively.

Features Utilized:

- Superfine Filtration:Removal of solid particles using 10-micron and 3-micron filter elements.

- Vacuum Dehydration Technology:Efficient moisture removal to bring levels below permissible limits.

- Ion Exchange Technique: Effective reduction of TAN values to prevent further corrosion and degradation.

- Inert Gas Blanketing:Ensures Electro-Hydraulic Control System ( EHC) system tank moisture control and ingress prevention.

Consumables Used

This plant managed to save:

- EH Oil Quantity:1200 liters.

- Filter Elements: 1 x 10-micron, 3 x 3-micron filters.

- Resin Consumption:36 liters.

Alongside the installation, Minimac’s service engineer provided training on FRF maintenance, contamination control, and the importance of oil analysis programs.

Results

Quantitative Outcomes:

- Total Cost Savings:₹1.5 Crore (₹1.05 Crore from avoiding downtime and ₹44 Lakh from eliminating oil replacement).

- Reduced TAN Values:Enhanced turbine reliability and availability.

- Extended Oil Life:Prevented degradation through contaminant and moisture control.

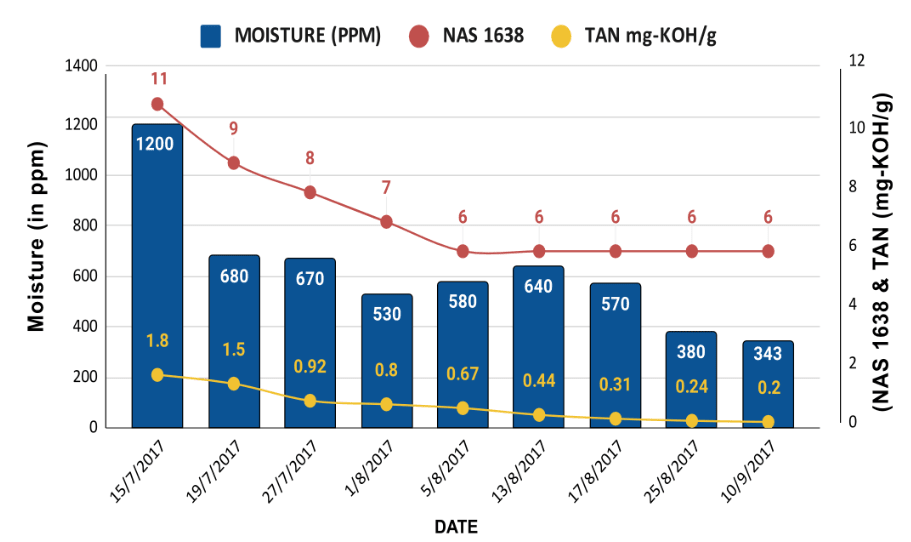

The above graph shows the trend analysis of NAS 1638, Moisture, and TAN value during the one-month installation of the reconditioning of EH oil at the customer site.

Qualitative Outcomes:

- Improved Turbine Performance:No more turbine hunting or sluggishness.

- Enhanced Reliability:Consistent and reliable operation of the turbine Electro-Hydraulic Control System ( EHC ).

- Positive Feedback:The client expressed satisfaction with the effectiveness of Minimac’s Electro-Hydraulic (EH) Oil Reconditioning System.

Conclusion

Minimac Systems' MLC LVDH TRIX-20 Electro-Hydraulic (EH) Oil Filtration System successfully addressed the challenges faced by the power plant, resulting in:

- ₹1.5 Crore Cost Savingsthrough oil replacement prevention and downtime avoidance.

- Improved Turbine Reliability and Availabilityby reducing Total Acid Number (TAN) and eliminating moisture.

- Extended Oil Life and Enhanced Performanceof the turbine Electro-Hydraulic Control System (EHC) system.

Discover more about our oil purification systems by Clicking Here