Power Plant Avoids ₹3.01 Crore Loss with Minimac Systems’ EH Oil Solutions

Executive Summary

A 2 x 600 MW power plant in Western India, utilizing a Chinese technology turbine, Electro-Hydraulic Control System (EHC) or the Digital Electro-Hydraulic System (DEH) was struggling with increasing Total Acid Number (TAN) and high moisture content in its Electro-Hydraulic (EH) oil. These issues led to severe operational challenges, including servo valve failure, unplanned shutdowns, and turbine hunting.

Minimac Systems implemented its MLC LVDH TRIX-20 EH Oil Reconditioning System, a comprehensive solution designed to eliminate solid contaminants and moisture and reduce TAN effectively. This intervention prevented a potential turbine shutdown worth ₹2.8 Crore and avoided oil replacement costs of ₹21 Lakh, resulting in total savings of ₹3.01 Crore.

Key Metrics:

- TAN Reduced:Restored EH oil quality using ion exchange purification.

- NAS 5 Achieved: Removed solid contaminants with superfine filtration.

- ₹₹3.01 Crore Saved:Prevented turbine shutdowns and oil replacement costs.

- Turbine Performance Improved:Eliminated hunting and valve failures.

Introduction

Minimac Systems is a leading provider of EH Oil Reconditioning Systems designed to enhance the performance and longevity of industrial lubricants. Our flagship product, the MLC LVDH TRIX-20 EH Oil Filtration System, offers cutting-edge solutions for contamination control, TAN reduction, and moisture removal.

Client Profile:

- Industry: Power Generation (Thermal Power Plant)

- Plant Capacity:2 x 600 MW

- Location: Western India

- Technology Used: Chinese Technology Turbine EHC System

The Challenge

Problem Statement: The power plant faced rapidly increasing TAN values and excessive moisture content in the EH oil of the turbine governing system. Contamination ingress and by-product formation severely degraded the oil quality, impacting the plant’s operational efficiency.

Impact of the Problem:

- Frequent Servo Valve Failures Hlead to turbine hunting and sluggishness.

- High TAN Valuecausing electro-kinetic erosion of EHC system components.

- Presence of Varnish & Silt obstructing spool clearance.

- Unplanned Shutdownsresult in generation loss and revenue loss.

The Solution

Implementation of Minimac Systems:

To address these issues, the MLC LVDH TRIX-20 EH Oil Reconditioning System was deployed. The system is specially designed to tackle EH oil degradation through a combination of advanced technologies.

Features Utilized:

- Superfine Filtration:Effective removal of solid contaminants.

- Vacuum Dehydration Technology:Comprehensive moisture removal.

- Ion Exchange Technique: Significant reduction of Total Acid Number (TAN).

- Inert Gas Blanketing:Prevention of moisture ingress in the EHC system tank.

Consumables Used

- EH Oil Quantity Processed: 1200 liters.

- Filter Elements Required: 10-micron (1 qty), 3-micron (3 qty)

- Resin Consumption: 36 liters

Minimac Systems' service engineers also provided training to the plant’s team on Fire Resistant Fluid - FRF, maintenance, contamination control, and the importance of a robust oil analysis program.

Results

Quantitative Outcomes:

- Cost of Oil Replacement Avoided: ₹21 Lakh

- Cost of Downtime Avoided:₹2.8 Crore (48 hours downtime prevention)

- Total Savings Achieved:₹3.01 Crore

- CO2 Emission Reduction: 14,400 kg of CO2 e / 0.0144 gigagrams of CO2 e.

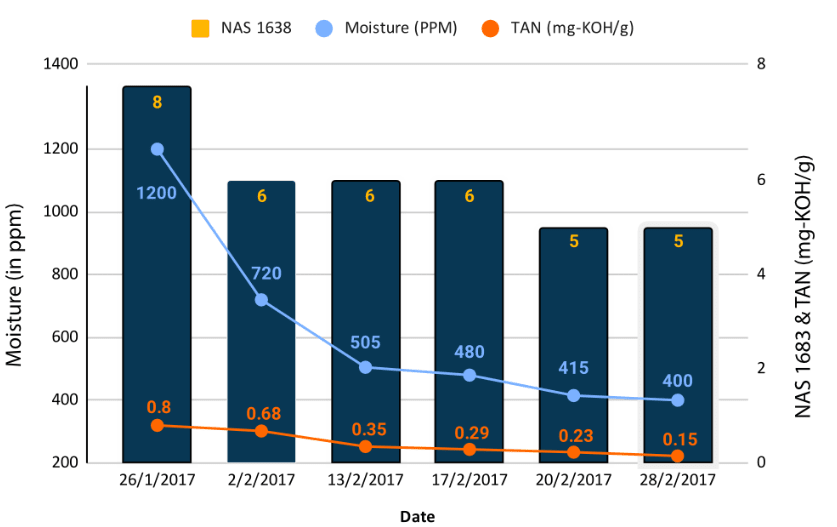

The above graph shows the trend analysis of NAS 1638, moisture, and TAN value around the one-month installation of the reconditioning of EH oil at the customer site.

Qualitative Outcomes:

- Enhanced Turbine Availability & Reliability.

- Extended Oil Life through effective contamination control.

- Prevention of turbine hunting and sluggishness.

- Improved understanding of Fire Resistant Fluid - FRF maintenance and oil analysis through expert training.

Conclusion

By implementing Minimac Systems’ MLC LVDH TRIX-20 EH Oil Reconditioning System, the power plant achieved:

- Significant cost savings of ₹3.01 Crore.

- Enhanced operational maintenance reliability and efficiency.

- Reduced environmental impact through CO2 emission reduction.

Minimac Systems' solution effectively addressed the client’s challenges, enhancing turbine reliability and extending EH oil life.

Discover more about our oil purification systems by Clicking Here