How Minimac Systems Successfully Saved ₹10 Crore with Proactive Oil Purification.

Executive Summary

Minimac Systems successfully addressed severe oil contamination challenges at a major 2340 MW power plant in West Bengal, India. Implementing FS, MLC-LVDH, and LVDH units significantly reduced moisture and solid contaminants, ensuring optimal oil cleanliness, preventing equipment failure, and generating cost savings exceeding ₹10 crore.

Introduction

Client Profile:

- Sector: Power Generation

- Lubricant Involved:Lube Oil

- Problem Type: Severe Oil Contamination and elevated NAS value in the M.O.T. and TDBFP.

- Solution Type:Minimac’s FS, MLC-LVDH, and LVDH

- Contract Type: Annual Rate Contract

A leading power generation company operating a 2340 MW power plant in West Bengal. The facility plays a crucial role in supplying electricity to the region and maintaining energy stability.

The Challenge

Problem Statement:

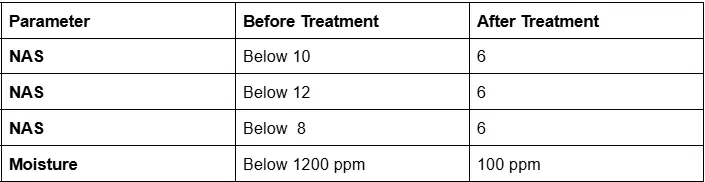

The plant faced severe contamination in its Main Oil Tank (M.O.T.) and Turbo Driven Boiler Feed Pump (TDBFP) oil, with moisture and solid particulates reaching unacceptable NAS levels (NAS 10, 12, and 8). If left unaddressed, this issue posed serious risks:

Impact of the Problem:

- Equipment Risks:High contamination levels threatened pumps, motors, valves, and bearings.

- Financial Losses: The risk of costly oil changes and equipment failures, leading to unnecessary expenditures.

- Operational Disruptions: Increased chances of unplanned downtime due to oil degradation.

- Environmental Impact: High contamination levels could lead to increased CO2 emissions from frequent oil replacements.

The Solution

Implementation of Minimac Systems:

To combat the contamination issue, Minimac Systems deployed a multi-step oil purification approach using:

Features Utilized

- FS (Filtration System): Removed solid contaminants from the oil.

- MLC-LVDH & LVDH (Vacuum Dehydration & Filtration Systems): Extracted moisture and fine particulate matter to restore oil purity.

- System Flushing:: Ensured clean oil was reintroduced, removing residual contamination.

- NAS Monitoring:Inline mesh inspections verified the system achieved the desired NAS level.

Results

Quantitative Outcomes:

- Cost Savings:Over ₹10 crore saved by avoiding oil changes and unplanned downtime.

- Environmental Impact:Prevented 596 KL of HP 46 grade oil from being replaced, reducing CO2e emissions.

Qualitative Outcomes:

- Enhanced Equipment Reliability:Clean oil minimized wear and tear, extending machinery life.

- Reduced Maintenance Costs:Lower contamination levels reduced the need for frequent maintenance.

- Improved Operational Efficiency: The risk of sudden failures was mitigated, ensuring smooth plant operations.

Conclusion

Summary of Benefits

By deploying FS, MLC-LVDH, and LVDH units, Minimac Systems effectively eliminated oil contamination, enhancing the reliability of critical power plant equipment. The intervention led to substantial cost savings, improved operational efficiency, and a reduced environmental footprint.

If your industry faces similar oil contamination challenges, contact Minimac Systems today to explore our advanced filtration solutions and ensure seamless equipment operations.

Learn More About Our Oil Purification Systems Solutions