Mastering Maintenance Strategies: Types, Benefits, and Impacts

Introduction:

Is your maintenance programme supporting your business well? Or do you wonder if there’s a smarter way to maximize your resources, minimize your downtime, and boost your bottom line? In this piece, we’ll uncover the keys to getting the hang of maintenance practices that can transform your operations. Here, you will learn the differences between these two methods and their abilities to improve the productivity of a system. By understanding this, you will be able to make better decisions as you work to maximize your maintenance activities and the impact they have on your organization.

Types of Maintenance Strategies

1. Preventive Maintenance

Maintenance by interruption consists of regular inspections and servicing of equipment to avoid unplanned downtime. Through periodical maintenance activities, projects can discover and address small problems early, before they grow into expensive issues. This is a proactive step to ensure reliability and efficiency.

2. Reactive Maintenance

Reactive maintenance, or run-to-failure maintenance, is a system where an asset is used, and only when it breaks can we take corrective action. Though it might appear as a cost saver in the short run, it may escalate the downtime, add to the cost of the long term, especially for high-value machines.

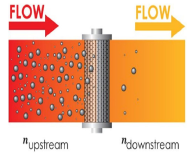

3. Predictive Maintenance

Predictive maintenance uses data analytics and continuous monitoring tools to predict when equipment will break down. Through maintenance in line with the actual conditions of equipment, excessive repairs can be eliminated, schedules can be optimized, and the proportion of available equipment can be maximized.

4. Proactive Maintenance

The main goal of proactive maintenance is to identify the causes of equipment failure before they occur. It is based on the analysis of the history, trends, follow-up, and preventive actions. The goal of proactive maintenance is to improve the reliability and efficiency of plant equipment over the long term by addressing risks at their root cause.

Pros and Cons of Maintenance Strategies

1. Preventive Maintenance

Pros:

- Reduced equipment downtime by scheduling maintenance proactively.

- Total life cycle investment with maintenance and service support.

- More work with less downtime.

Cons:

- High upfront investment in labor, tools, and scheduling.

- Intermittent operational disruption for planned maintenance.

2. Reactive Maintenance

Pros:

- Ease: It addresses problems and unusual occurrences.

- Reduced front-end costs by not investing in scheduling systems.

Cons:

- Unscheduled downtime can be crippling.

- More high bills for repairs and stress at work.

3. Predictive Maintenance

Pros:

- Real-time data-driven schedules.

- Cut downtime with proactive problem identification.

- Get practical, data-driven insights for making better decisions.

Cons:

- High technology and expertise implementation costs.

- Reliability of the predictions relies on the availability of accurate data.

4. Proactive Maintenance

Pros:

- Addresses the root cause of failures to help prevent the same failure from happening again.

- Greater machine reliability and long-term cost savings.

- Long-run managerial effort.

Cons:

- More initial investment in equipment and expertise.

- The complicated application needs to be analyzed deeply.

For More Information About Maintenance - Click Here

Selecting the Appropriate Maintenance Strategy for Your Business

Choosing the right maintenance strategy involves a lot of thinking about your operational requirements, the resources that you have at your disposal, and how much risk you're willing to take. Preventative or predictive maintenance is often the best strategy, especially for anything critical, but then critical machines also should never be frozen and instead kept in an operational readiness state. They are also under the burden of assessing workforce capacity and technology. Predictive maintenance is effective, but expensive in terms of technology and expertise. Preventive maintenance, although costly, can act as a compromise for the companies that need reliability without the expenses and complexity of predictive setups. After all, the selected approach should reflect the company’s objectives and business directives, in the long run.

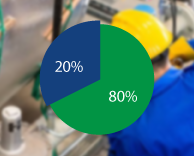

How Maintenance Strategies Impact Your Wallet

How effective maintenance strategies directly impact your organization, with the efficiency of a plant and its maintenance having a direct bearing on your organization’s bottom line. By utilizing preventive and predictive maintenance, unplanned downtime and expensive emergency repairs are reduced, allowing for a seamless workflow and greater output. It also facilitates better inventory management and resource allocation, thus lowering other operational costs associated with maintenance.

However, apart from saving costs, proper maintenance of equipment boosts customer satisfaction by ensuring timely delivery and quality output. By embracing this, you create brand loyalty among your customers and also enhance and strengthen your brand identity, thus giving you a strong competitive advantage.

To implement a successful maintenance strategy:

- Make a plan: What do you want to achieve, who is doing what, and when? Educate personnel about the comprehensive aspects and breakdown of how the plan is functioning or what needs to be implemented.

- Use Maintenance Management Software: Take advantage of maintenance management software to schedule, run analytical performance data analysis, and streamline processes.

- Monitor Performance: Measure equipment downtime, expense of fixes, available personnel, and other efficiency markers to assess performance. But this information can help to improve and adjust your strategy.

Conclusion

Your guide to Operational Excellence and Financial Success: Mastering Maintenance Strategies.' An assessment of the benefits and trade-offs for each approach allows decision-making best suited for an organization. Maintenance is preventive or predictive, which significantly reduces downtime, improves reliability, and thus strengthens the bottom line. While you do need to adopt technology and establish an environment of continuous improvement, the overall result is that your organization will be ready for growth & strength in all of the years to come.

Learn more about our services and industry insights by visiting our official LinkedIn page: Minimac Systems