EH Oil Reconditioning System Saved ₹5 Crore for 1200 MW Coal-Fired Thermal Power Plant

Executive Summary

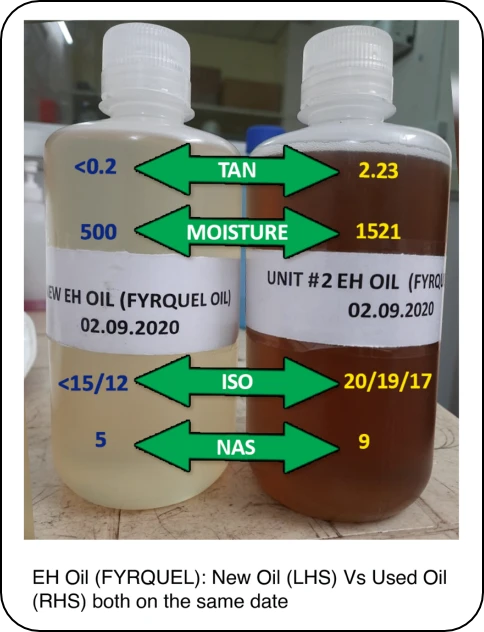

A 1200 MW Coal-Fired Thermal Power Plant in Southern India, equipped with an Indo-Chinese Turbine Electro-Hydraulic Control System (EHC) or the Digital Electro-Hydraulic System (DEH), was experiencing frequent turbine tripping and severe productivity loss due to Servo Valve (Moog Valve) failure. By implementing Minimac Systems’ EH Oil Reconditioning System – MLC LVDH TRIX 20, the plant achieved enhanced turbine reliability, extended oil life, and avoided a potential loss exceeding ₹5 Crores.

Key Metrics:

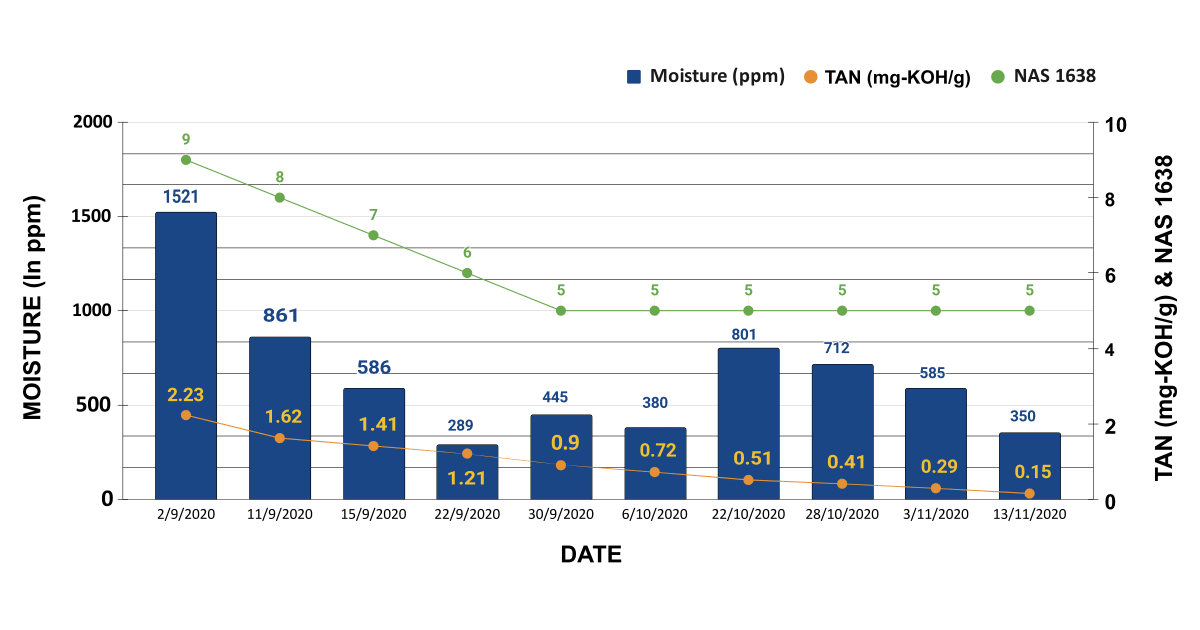

- Reduced Total Acid Number (TAN) significantly.

- Achieved NAS 5 cleanliness through advanced filtration.

- Saved over ₹5 Crores by preventing unexpected shutdowns.

- Increased Turbine Reliability by eliminating servo valve hunting and sluggishness.

- Extended Oil Life through moisture removal and contamination control.

Introduction

Background Information:

Minimac Systems specializes in providing innovative oil filtration and reconditioning solutions to various industries, including power generation, mining, steel, and manufacturing. The MLC LVDH TRIX 20 EH Oil Reconditioning System is a state-of-the-art solution designed to enhance the reliability of Turbine Electro-Hydraulic Control Systems (EHC Systems by efficiently removing contaminants, moisture, and reducing TAN.

Client Profile:

- Industry: Power Generation (Coal-Fired Thermal Plant)

- Plant Capacity:1200 MW

- Location: Southern India

- System Used: Indo-Chinese Turbine Electro-Hydraulic Control System (EHC)

The Challenge

Problem Statement: The power plant was suffering from frequent turbine tripping, resulting in significant productivity loss. The main issue was traced to the failure of the Servo Valve (Moog Valve), which exhibited hunting and sluggish behavior.

Impact of the Problem:

- Inconsistent turbine operation due to frequent tripping.

- Decreased power generation efficiency.

- Risk of unplanned shutdown leading to financial losses exceeding ₹5 Crores.

- Improper Oil Analysis Program, failing to detect and address oil contamination effectively.

- Inadequate Operation Practices due to the partially closed solenoid valve of the LVDH vacuum line, reducing vacuum efficiency.

The Solution

Implementation of Minimac Systems:

Minimac Systems deployed the MLC LVDH TRIX 20 EH Oil Reconditioning System to comprehensively address the challenges faced by the power plant. A trained service engineer provided installation and training to ensure optimal operation and maintenance.

Features Utilized:

- Superfine Filtration:Achieved NAS 5 cleanliness using 10-micron and 3-micron filter elements.

- Vacuum Dehydration Technology:Effectively removed moisture from the oil, enhancing overall purity and preventing valve malfunction.

- Ion Exchange Technique: Reduced Total Acid Number (TAN), ensuring longer oil life and improved performance.

- Inert Gas Blanketing:Maintained the Electro-Hydraulic Control System (EHC) system tank in a moisture-free environment, preventing moisture ingress and enhancing turbine reliability.

Results

Quantitative Outcomes:

- Filter Consumption: 1 Qty of the 10-micron filter element and 1 Qty of the 3-micron filter element to achieve NAS 5 cleanliness.

- Resin Consumption:36 Liters.

- Total Equipment Running Hours:698 Hours.

- Prevention of ₹5 Crore Loss:Effective implementation of the MLC LVDH TRIX 20 system prevented a major shutdown.

Qualitative Outcomes:

- Enhanced turbine reliability by eliminating Moog Valve hunting and sluggishness.

- Improved oil quality through effective contamination control and moisture removal.

- Client feedback: “Minimac Systems' solution proved to be a game-changer. Their innovative Electro-Hydraulic (EH) Oil Reconditioning System not only resolved our immediate issues but also ensured reliable turbine performance and saved us from a catastrophic financial loss.”

Conclusion

The 1200 MW Coal-Fired Thermal Power Plant significantly improved its operations through the MLC LVDH TRIX 20 EH Oil Reconditioning System. By eliminating contamination, controlling moisture, and maintaining oil quality, the plant achieved:

- Enhanced turbine reliability.

- Extended oil life.

- Improved efficiency and cost savings

- Prevention of a ₹5 Crore financial loss.

Discover more about our oil purification systems by Clicking Here