Moisture in Oil: Causes, Effects, and Prevention Strategies for Machinery Lifespan

Introduction

Water contamination in oil is one of the most common causes of industrial machinery, hydraulics, and lubrication system failures. Moisture, in any amount, can wreak havoc from corrosion to wasted lubrication. Therefore, to assure the durability and functionality of the machinery, the causes, consequences, and solutions of Moisture pollution in oil should be recognized. In this article, we will break down the entry routes of Moisture into the lubricants, the threat it leads to your machinery, and how to manage & prevent Moisture contamination for the most efficient operation of your equipment.

How does moisture-contaminated oil ?

There are multiple ways moisture can contaminate oil. Knowledge of the main contamination sources is the first step in effective management and prevention of contamination.

Common Causes of Moisture Contamination:

- Condensation: Condensation is a frequent source of Moisture contamination in machines that work at different temperatures. Moisture vapor condenses in the system when oil cools, becoming a contaminant in the lubricant.

- Leaks in Seals and Gaskets: Moisture can infiltrate the equipment as seals and gaskets wear down and fail as time goes by. This is particularly an issue in humid conditions where moisture from outside can enter the system.

- Humidity Ingress: Moisture from the air, especially in high-humidity conditions, can enter the oil if the systems are poorly sealed or if desiccant driers are absent.

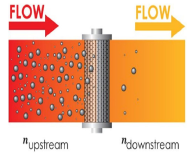

Types of Moisture Contamination in Oil

- Free Moisture: Free Moisture develops when the oil is too saturated, and Moisture collects on the tank or system oil filter surface. This is the most straightforward kind of infestation to recognize, however, it calls for quick action.

- Emulsified Moisture: Moisture can also mix in the oil to form an emulsion, which is more difficult to separate. This is where Moisture is emulsified (broken into tiny droplets) and suspended in the lubricant.

- Dissolved Moisture: The moisture that dissolves in oil is generally considered unseen, which can lead to a lot of damage over time, especially in the case of high-precision systems like hydraulics and turbines.

The Consequences of Moisture Contamination

Contamination of oil from moisture can be fatal for machine performance. Even slight amounts of contamination can result in big problems that lower efficiency and increase the risk of failure.

- Degradation of Lubrication Property: High levels of moisture change the oil's viscosity and its ability to lubricate the equipment. Moisture - Since the filter captures water as well as particles, the oil loses even more of its ability to reduce friction and wear, resulting in increased temperatures and internal stresses on components.

- Corrosion and Rust Development: Water contained in oil can cause a reaction with metals, which leads to corrosion and rust. This damage can be expensive to repair and can also result in machine downtime. Some badly rusted parts may need to be replaced, which can be very costly.

- Increased Component Deterioration: Lube and moisture mixed in just the right proportions can accelerate abrasive wear. The absorption of moisture hastens the collapse of lubrication, increasing friction between moving components that move, wearing out and failing prematurely.

- Higher Equipment Damage Risks: Eventually, water in oil can lead to damaging failures. Plants can experience unscheduled machine failures, risking production downtime and safety.

- Moisture Contamination in Oil Monitoring: Moisture contamination within the product is important in preventing expensive repairs and extended downtime.

- Visual Check: The easiest test you can perform on oil for contamination is simply to examine it visually for any changes in color or droplet separation. You may see a layer of moisture forming at the bottom of your oil container if you have free Moisture.

Advanced Testing Techniques:

- Karl Fischer Titration: Most accurate for Moisture in oil-filled füllmenst. It's capable of sensing even tiny amounts of Moisture -- ideal for precision work.

- Crackle Test: The oil will begin making a crackle or sizzle sound as it heats when there is just a bit of moisture present. This method is also particularly effective for testing emulsified Moisture.

- Moisture Sensors: Current moisture sensors are able to be mounted and detect Moisture content in oil 24/7, will alarm the Operator of contamination before damage is done.

For More Information About How Minimac Helps you to remove moisture contamination -Click Here.

Preventive Measures for Moisture Contamination

Oil in, mole’s out! There are many ways to help protect yourself from Moisture, some ways are more effective than others. As in any form of contaminated fuel, there will always be a healthy debate as to which is more dangerous, how long it will be before “it” all goes pop, and what is ‘It’ in the first place! Prevention is 1000 times better than a cure, so how can we reduce the risks of contamination in oil by Moisture?

- Sealing Systems and Design Improvements: Make sure that plugs and gaskets are still in good condition, so that you don’t have leaks. Depending on your situation, you might be able to install better sealing systems or modify your machinery to prevent Moisture from getting in.

- Proper Storage of Lubricants: Keep lubricants in airtight containers and under controlled humidity. This also reduces the chance of condensation and keeps external moisture out of the oil.

- Use of Desiccant Breathers: Desiccant breathers soak up moisture in the air before it enters the system. It's a great way to do things, especially for things that live outside and have to be subject to varying weather conditions.

- Best Practice for Monitoring & Maintenance: Inspect and service equipment frequently to identify possible Places for Moisture ingress. Plan regular oil inspection and a preventative maintenance program to make sure that seals, breathers , and other elements are working efficiently.

Solution to Remove Moisture Contamination?

- Centrifugation: It employs centrifugal force whereby Moisture is separated out of the oil. This is a very good process to eliminate Free Moisture and emulsified Moisture from large quantities of oil.

- Vacuum Dehydration Units (VDUs): Vacuum Dehydration Units (VDUs)Induce Vacuum Pressure to Evaporate Moisture. An ideal solution really for high-performance systems, which require very low moisture levels.

- Moisture Absorption Filters and Removal Additives: The most commonly used moisture removal additives and a few absorption filters are also available for the elimination of Moisture from oil, especially in systems that require complete elimination.

Moisture contamination cost issues

Moisture Contamination – one of the most costly issues. Direct costs comprise fixing or replacing damaged parts and lubrication. Indirect costs like unplanned downtime, unnecessary productivity losses, and higher energy consumption can escalate as well. The best way to avoid these expenses is to catch and treat them early.

Conclusion

The presence of moisture in a machine, or oil contamination

with moisture, is a secret killer of your machines. It can cause

significant harm, such as corrosion, reduced lubricant efficacy,

and accelerated wear. Fortunately, you can prevent costly failures

by detecting, mitigating risk, and removing them, but the key is

using the right methods for each. That means not only keeping a

close eye on things but also going above and beyond to set

limitations, which enables your systems to run without a hitch and

operate for as long as possible.

Learn more about our services and industry insights by visiting

our official LinkedIn page:Minimac Systems