Preventing Catastrophic Shutdown at Chattisgarh 2980 MW Thermal Power Plant

Executive Summary

Minimac Systems successfully addressed severe contamination issues in the FRF (Fluid Reservoir Fluid) oil of Unit 4 at a leading thermal power plant in Chhattisgarh. By deploying advanced oil purification technology, Minimac reduced the Total Acid Number (TAN), National Aerospace Standard (NAS) contamination level, and moisture content, preventing potential failures and operational disruptions.

Introduction

Client Profile:

- Sector: Power Generation

- Region:Chhattisgarh, India

- Site: Chhattisgarh

- Plant Capacity: 2980 MW (Phase I: 3 x 660 MW, Phase II: 2 x 500 MW)

- Technology: Super Critical Boiler Technology (Phase I)

Chhattisgarh is one of India's largest thermal power plants, with a total capacity of 2980 MW. Operating on supercritical boiler technology, it plays a crucial role in India's power generation sector.

The Challenge

Problem Statement:

Unit 4 of Chhattisgarh faced rapid FRF oil degradation, leading to:

- Elevated TAN (Total Acid Number): Indicating acid formation that could corrode components.

- Increased NAS (Particle Contamination Level):Signifying solid contaminants that could cause wear and tear.

- High Moisture Content: Leading to hydrolysis, acid formation, and microbial growth.

Impact of the Problem:

- Potential Catastrophic Failure:Contaminated oil threatened the turbine governing system, risking a complete shutdown.

- Financial Losses: A shutdown could have cost approximately Rs. 1.5 crores per minute.

- Operational Disruptions: Downtime would severely impact plant productivity and efficiency.

The Solution

Implementation of Minimac Systems:

To combat the contamination issue, Minimac Systems deployed a high-performance oil purification system, incorporating:

- LVDH (100 LPM): Vacuum dehydration for moisture removal.

- Nitrogen Dehydrator (30 LPM):Eliminating dissolved gases.

- Resin Skid (8 LPM): Acid removal to restore TAN levels.

- Filtration System (150 LPM):Removing solid contaminants to reduce NAS.

Features Utilized

- High-Efficiency Contaminant Removal: Targeted elimination of moisture, acids, and solid particles.

- Rapid Deployment & Effectiveness: Achieved significant results within days of installation.

- Advanced Oil Restoration Technology: Ensuring long-term oil quality maintenance.

Results

Quantitative Outcomes:

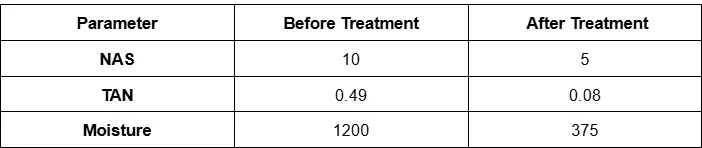

- Moisture and NAS Reduction:Achieved within three days of installation.

- TAN Restoration:Lowered from 0.49 to 0.08 within one month, exceeding expectations.

- Operational Continuity:Prevented downtime, ensuring seamless plant operations.

Qualitative Outcomes:

- Eliminated Shutdown Risk:Prevented catastrophic turbine failure.

- Cost Savings: Averted potential losses worth crores, including oil replacement costs (Rs. 10 million).

- Sustainability Benefits: Improved oil conditions reduce carbon emissions and enhance environmental sustainability.

Conclusion

Summary of Benefits

Minimac Systems' oil purification technology successfully restored FRF oil quality at Chhattisgarh, preventing a potential plant shutdown and financial disaster. By leveraging advanced purification solutions, the plant maintained operational efficiency, protected critical assets, and ensured long-term reliability.

Client Trust & Satisfaction

Upon witnessing the rapid improvement in oil quality and system performance, Chhattisgarh gained confidence in Minimac’s solutions, strengthening our position as a trusted partner in oil purification.

Facing similar contamination challenges? Contact Minimac Systems today to explore how our innovative oil purification solutions can enhance your equipment’s reliability and efficiency.

Learn More About FRF Conditioning Systems Solutions