How Minimac Systems Enhanced Oil Purity in the Oil & Gas Sector.

Executive Summary

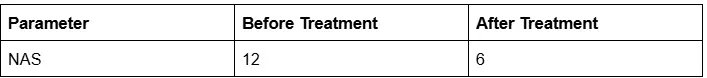

Minimac Systems successfully implemented High-Velocity Flushing (Oil Flushing) with ISO VG 32 Grade oil to resolve contamination issues in an Oil & Gas project in Andhra Pradesh. This intervention reduced NAS 1638 contamination levels from unspecified high levels to Class 6, ensuring optimal machinery performance.

Introduction

Client Profile:

- Industry:Oil & Gas Refinery

- Location:Andhra Pradesh, India

- Facility Type:Oil Refining and Processing Plant

- Oil Type:ISO VG 32 Grade - Hydraulic Oil

- Oil Quantity:Approximately 10000 liters

An oil and gas refinery in Andhra Pradesh faced challenges with oil contamination, impacting their machinery’s efficiency and reliability.

The Challenge

Problem Statement:

The client encountered severe contamination issues, with NAS 1638 and MESH 100 standards not meeting the required cleanliness level. This posed risks to equipment longevity and operational efficiency.

Impact of the Problem:

- Increased risk of machinery failure.

- Higher maintenance costs.

- Reduced operational efficiency.

The Solution

Implementation of Minimac Systems:

Minimac Systems deployed its High-Velocity Flushing (Hot Oil Flushing) solution using ISO VG 32 Grade oil. This method effectively removed contaminants and ensured oil cleanliness met industry standards.

Features Utilized

- High-Velocity Flushing technique

- Use of ISO VG 32 Grade oil

- Targeted removal of contaminants based on NAS 1638 and MESH 100 standards

Results

Quantitative Outcomes:

Qualitative Outcomes:

- Enhanced operational efficiency

- Reduced maintenance costs and downtime

Conclusion

Summary of Benefits

Through Minimac Systems’ advanced oil flushing technology, the company significantly improved its oil cleanliness standards, ensuring smoother and more reliable operations.

If your business faces similar contamination challenges, contact Minimac Systems today to discover how our solutions can enhance your equipment's reliability and efficiency.

Learn More About Our Flushing Skid Solutions and Minimac Operation and Maintenance Services