Minimac Systems Prevents INR 10 Crore Loss with Oil Purification at 3000 MW Power Plant

Executive Summary

A leading 3000 MW thermal power plant in Uttar Pradesh faced a severe operational threat due to deteriorating FRF oil quality. The presence of high NAS, TAN, and moisture levels posed risks of turbine governing system failure, potentially leading to plant shutdown and massive financial losses.

Minimac Systems swiftly deployed its advanced oil purification technology, including Low Vacuum Dehydrators, Nitrogen Dehydrators, and Resin Skid Systems, to restore the oil's optimal quality. This intervention prevented downtime, enhanced operational efficiency, and resulted in cost savings worth crores of rupees.

Introduction

Client Profile:

- Sector: Power Generation

- Lubricant Involved:FRF Oil

- Problem Type: Elevated NAS and TAN

- Solution Type: Low Vacuum Dehydrators - 100 LPM, Nitrogen Dehydrators - 20 LPM, Resin Skid - 20 LPM, F.S - 150 LPM

A 3000 MW thermal power plant in Uttar Pradesh plays a crucial role in the region's power supply, relying on FRF oil for turbine governing system operations. Ensuring oil purity is critical for uninterrupted functionality.

The Challenge

Problem Statement: The plant faced critical contamination in FRF oil used across units 1, 2, and 4. The key issues included:

- Elevated NAS Levels: Indicating excessive particulate contamination

- High TAN Levels: Signifying oil acidity and potential corrosion risks

- Excessive Moisture: Leading to compromised lubrication and system failure risks

Impact of the Problem:

- Equipment Risks:Contaminated oil threatened the reliability of the turbine governing system, increasing the risk of a complete plant shutdown.

- Operational Disruptions: Failure could result in production halts, severely impacting power distribution.

- Financial Losses: A full shutdown would lead to estimated losses of INR 1.5 crores per minute, along with additional costs for repairs and replacements.

The Solution

Implementation of Minimac Systems:

To counteract the contamination challenge, Minimac Systems deployed a comprehensive oil purification system, integrating multiple advanced solutions:

- Low Vacuum Dehydrators (LVDH) - 100 LPM: Removed moisture and volatile contaminants.

- Nitrogen Dehydrators - 20 LPM: Reduced moisture to optimal levels.

- Resin Skid - 20 LPM: Eliminated acidic components, improving oil acidity.

- Filtration System (F.S) - 150 LPM:Enhanced overall oil quality by removing solid contaminants.

Results

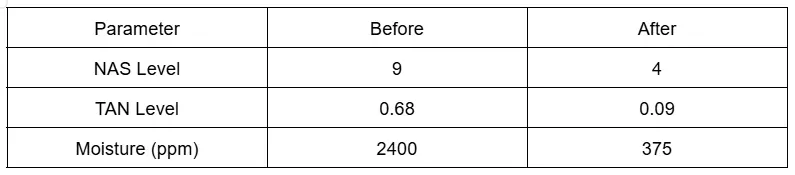

Quantitative Outcomes:

- Significant reduction in moisture levels within three days.

- Restoration of oil quality to industry-acceptable standards.

Qualitative Outcomes:

- Prevented a potential shutdown,saving an estimated INR 10 crores.

- Enhanced operational efficiency,ensuring smoother turbine performance.

- Reduced environmental impact,lowering carbon emissions through optimized oil usage.

Conclusion

Summary of Benefits

By deploying its advanced oil purification systems, Minimac Systems successfully mitigated contamination risks, ensuring uninterrupted operations at the 3000 MW power plant. The intervention saved crores of rupees, enhanced machinery reliability, and improved overall efficiency.

If your industry faces similar oil contamination challenges, contact Minimac Systems today to explore our advanced oil purification solutions and safeguard your critical assets.

Discover more about our oil purification systems by Clicking Here