How Minimac Systems Restored Stability at the World’s Largest Refinery.

Executive Summary

Minimac Systems successfully tackled a critical contamination issue at the world’s largest Refinery Off-Gas Cracker (ROGC) complex in India. The frequent tripping of compressors due to lube oil contamination threatened plant operations and production efficiency. By deploying FS-500 oil filtration systems, Minimac effectively flushed out contaminants from lube oil coolers, stabilizing compressor performance and preventing further production losses.

Introduction

Client Profile:

- SectorOil and Gas

- Lubricant Involved:Lube Oil

- Problem Type:Contamination in the new compressor led to its frequent tripping.

- Solution Type:Minimac's FS-500 Oil Filtration Systems

- Contract Type: Annual Maintenance Contract

The ROGC complex, a global leader in the petrochemical sector, has an ethylene production capacity of 1.7 MMTPA. As a crucial component of India’s refinery infrastructure, the uninterrupted operation of its compressors is vital for maintaining production efficiency and minimizing downtime.

The Challenge

Problem Statement:

Following an equipment overhaul, improper flushing of the lube oil piping and coolers led to contamination in the lube oil system. This resulted in:

- Frequent compressor tripping during startup

- Choked filters in the lube oil consol

- Increased risk of equipment failure and production halts

Impact of the Problem:

- Equipment Risks: Contaminants increase friction and wear, clog filters, and restrict oil flow.

- Operational Disruptions: Recurring compressor tripping threatened plant productivity.

- Financial Losses: Unresolved contamination could have led to losses worth crores due to production downtime and equipment damage.

The Solution

Implementation of Minimac Systems:

To address the contamination challenge, Minimac Systems deployed its FS-500 oil filtration systems, ensuring thorough flushing of lube oil coolers.

Features Utilized

- FS-500 Advanced Oil Filtration System:High-efficiency contaminant removal technology.

- Reynolds Number-Based Flushing:Ensured high turbulence to dislodge and remove contaminants.

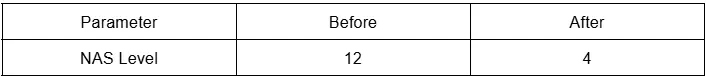

- Mesh Inspection & NAS Readings:Verified system cleanliness before and after flushing.

Results

Quantitative Outcomes:

- Mesh Inspection:Before flushing, filters were clogged with debris. After flushing, they were completely clear, ensuring unrestricted oil flow.

- Project Completion:Flushing was conducted across six compressors, taking 5 to 43 days per unit.

Qualitative Outcomes:

- Enhanced Equipment Reliability: Compressor tripping was completely eliminated.

- Operational Efficiency:Improved lubrication ensured smooth compressor operations.

- Significant Cost Savings:Prevented production losses and potential equipment failures.

Conclusion

Summary of Benefits

By deploying the FS-500 filtration system, Minimac Systems successfully restored stability at the ROGC complex. This intervention enhanced compressor reliability, protected critical machinery, and prevented costly downtime.

If your industry faces similar contamination challenges, contact Minimac Systems today to explore our advanced oil filtration solutions.

Learn More About Our Oil Filtration Systems Solutions