Minimac TAN Reduction in Control Fluid: 0.23 to 0.08 mgKOH/g

Executive Summary

Minimac Systems successfully implemented a customized Oil Purification System for a 2600 MW coal-based thermal power plant in Chhattisgarh. The plant faced challenges of high TAN values, excessive moisture, and fluctuating NAS values, which threatened unit stability and generation efficiency. Using advanced Nitrogen Blanketing Systems, TAN Reduction Technology, and Oil Purification Machines, Minimac Systems delivered exceptional results.

Key Metrics:

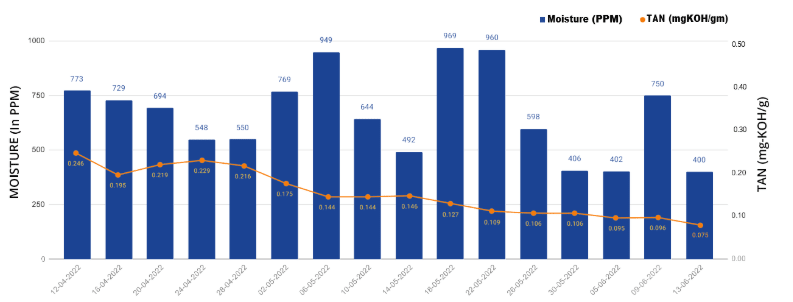

- Reduced Total Acid Number (TAN): From 0.246 to as low as 0.074 mgKOH/gm.

- Achieved NAS 5 Cleanliness: Through advanced multi-stage filtration.

- Cost Savings of ₹6.35 Crores: ₹3.2 Cr from oil replacement + ₹3.15 Cr from avoided downtime.

- Increased Turbine Reliability:Eliminated servo valve hunting and sluggish response.

- Extended Control Oil Life:Via moisture removal and contamination control.

Introduction

Minimac Systems specializes in providing customized oil filtration, purification, and TAN reduction solutions for various industries, including thermal power plants. The situation was examined by Minimac Operations and Maintenance Service (MOMS).Three machines - Nitrogen Blanketing TMR unit (100 LPM), Oil purification MLC-LVDH-TRIX (50 LPM), and TAN reduction— Resin filter modified in cartilage format were deployed to address the issue.

Our Minimac Operations and Maintenance Service (MOMS) ensures a hassle-free experience by providing trained manpower, consumables, and equipment as part of comprehensive maintenance services.

Client Profile:

- Industry: Thermal Power Generation

- Location: Chhattisgarh, India

- Capacity: 2600 MW coal-based thermal power plant

The Challenge

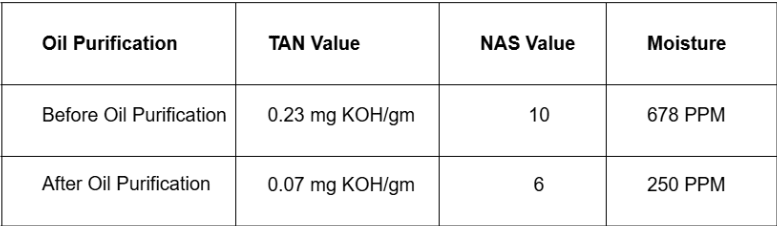

Problem Statement: The power plant was experiencing unstable operation due to high Total Acid Numbers (TAN), excessive moisture content (678 PPM), and fluctuating NAS values (NAS 10). This instability was jeopardizing the turbine governing system's performance, potentially leading to generation loss and unit outage.

Impact of the Problem:

- Risk of generation loss and unit downtime.

- Reduced operational efficiency due to inconsistent control fluid quality.

- Potential fire hazards and safety concerns.

- High replacement costs of control fluid (estimated at ₹3.2 Cr).

The Solution

- The Nitrogen Generation Unit (TMR) was deployed and installed at the client's site. The salient features of the TMR unit are - 99.9% pure nitrogen, a dew point less than -15 degrees Celsius, and a dedicated moisture condensing unit.

- For Nitrogen Blanketing, TMR–100 LPM had a flow regulator of 0-150 LPM.

- Oil purification machine MLC-LVDH-TRIX-50 for NAS & moisture reduction was installed.

- Installed 12 new resin filters for TAN reduction in existing recirculation units.

- Before the oil conditioning process, the TAN >=0.210 mg KOH/gm (Electronic method) and 0.246 mg KOH/gm (manual titration), which was reduced after oil purification to TAN <= 0.097 mg KOH/gm (Electronic method) and 0.124 mg KOH/gm (manual titration).

- For further improvement in TAN, the oil vapor extraction fan(OVEF) was throttled in the range of 50-55%, with the support of the user.

- They had an LVDH machine, and the NAS standard to be maintained as per the PO was 10+. We gave a better result without the replacement of the NAS filter.

- Minimac provided trained manpower and other consumables under the MOMS (Minimac Operations and Maintenance Service) offering. Minimac has charged resin in an 8-cycle with 3 hrs intervals. 24hrs resin charge KPI was 0.074 mgKOH/gm.

Features Utilized:

- Moisture Control:Achieved by deploying a dedicated moisture condensing unit.

- TAN Reduction:Optimized resin charging in an 8-cycle pattern to lower TAN to 0.074 mgKOH/gm.

- NAS Control:Improved NAS from 10 to 6 through customized purification techniques.

- System Throttling:Enhanced TAN reduction by optimizing Oil Vapor Extraction Fan (OVEF) operation.

Results

Quantitative Outcomes:

- Cost Savings: ₹6.35 Cr (₹3.2 Cr in oil replacement + ₹3.15 Cr in downtime prevention).

- CO2e Reduction: 1,92,000 kg (0.192 gigagrams).

Qualitative Outcomes:

- The client reported significantly improved turbine stability and enhanced control fluid reliability.

- Smooth execution with zero downtime and no spillage.

- Customized solutions exceeding client's expectations.

Conclusion

Minimac Systems’ customized oil purification solution provided the client with substantial cost savings, extended control fluid life, reduced environmental impact, and improved operational stability. The project’s success highlights the efficiency and reliability of Minimac’s advanced Oil Purification and TAN Reduction Systems.

Discover more about our oil purification systems by Clicking Here