Can all contaminants be seen with naked eyes?

This is part 2 of the #knowyouroil series, wherein we will dive into Particle Contamination. When we mention contamination, the first thing that strikes to our mind is the solid particles which we can see or touch. However, what we do not realize is how small the particle can actually be to start causing wear and tear to your machines, and not all contaminants are visible to the naked eyes. By then isn't too late to wait, is it?

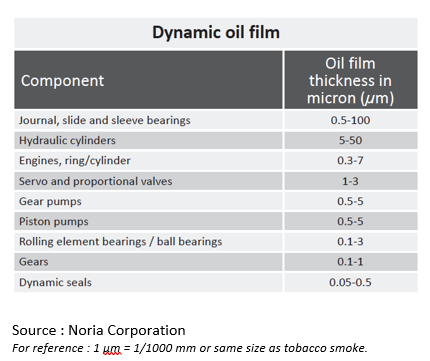

To answer the above questions, we first need to know the real clearance of different lubrication films formed in either rolling >> or rotating components, which is necessary to provide proper lubrication. The oil film thickness that exists in the, for example, mechanical part of the machinery is measured in microns (µm), or (1 millionth of 1 meter.)

For queries related to Oil Testing, follow:

https://www.linkedin.com/company/minimacsystemsprivatetlimited

Below are the finest tolerances found in different types of

components.

When small particles, which cannot be seen through human eyes, pass through the critical machine parts under load, they create small microtears which get transformed into cracks over a period of time due to continuous stress and strain conditions, leading to the fine generation and hence increasing contamination.

The contaminants that are considered to be most damaging are from size 2 to 20 µm and avoiding these is key to keeping your machinery breakdown-free.>

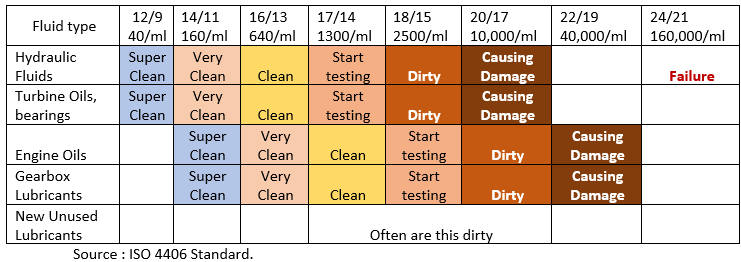

But it is also important to understand when to call the oil clean and when dirty, as it is understood that changing oil very frequently and maintaining it every time is not feasible.

The chart below shows us what particle levels are admissible and what harms our system.

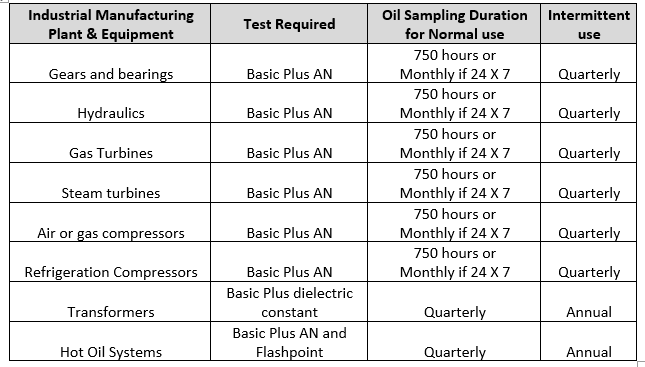

But knowing this is not enough if we don’t know when to get oil sampling and testing done. The below chart provides an estimation for testing and the type of test to be conducted.

Get your machine's oil check today with our technical expert call

+91 7030901266. Ask for a brochure today.

We at Minimac System Pvt. Ltd. not only design a maintenance

schedule for your lubrication oil but also provide OIL TESTING and

FILTRATION services and the filtered oil complies with the ISO

standard of Super Clean oil, as we stand for MINImum MAChinery

Maintenance.

Click Here.