How Flushing Solves Varnish Problems: The Essential Maintenance Solution for Reliable Equipment Performance

Introduction to Oil Varnish

What Is Oil Varnish?

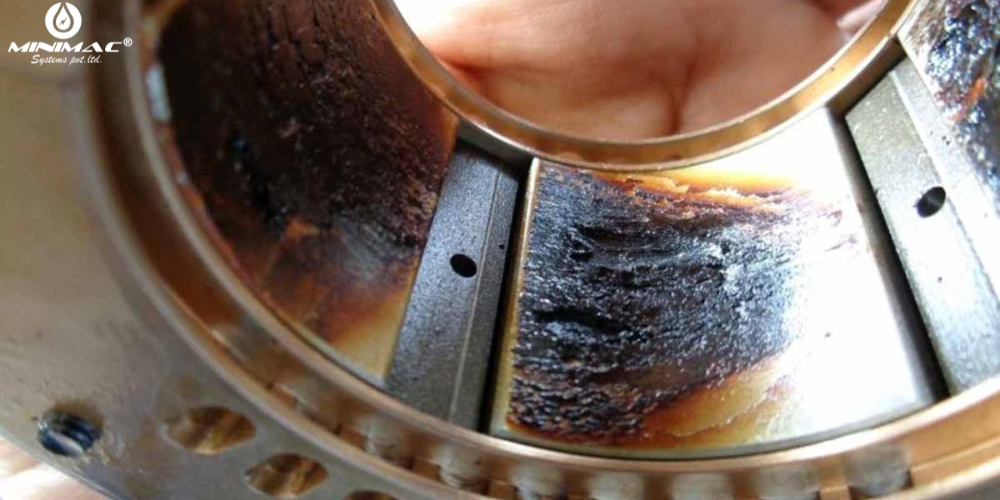

Oil varnish is a residue that is sticky like honey, more resin-like and forms on surfaces in a machine. Normally, it clings to metal surfaces due to the breakdown of lubricants and can build up over time. This results in a gentle layer on machine parts, which in turn alters functioning and decreases the machine's lifetime, while varnish builds up on surfaces that affect critical clearances and finishes, starving components of lubrication.

Why Industrial Oil Varnish Matters

Don′t overlook oil varnish and compromise your oil system – it will lead to inefficient operations, breakdown, and high maintenance costs. In industries with large machinery, like manufacturing, power generation, and transportation, varnish management is vital to maintaining machine reliability and efficiency.

The Role of Maintenance in Addressing Varnish Problems

Proper maintenance is the first step in eliminating most of the

varnish and varnish-related operational troubles. Over time, even

with good practice methods such as regular checks of lubricants,

filtration, and inspections, varnish will ultimately form,

although these practices could lessen the degree of formation.

Consequently, maintenance teams are challenged to

discover increasingly preventative ways to eliminate varnish

deposits and mitigate their effects.

To combat varnish in the past decades, we have scrubbed and

brushed everything that looked black and grimy, and while this is

laborious, time-consuming, and never really fully effective, it

was all done "the old way". Fortunately, flushing is a new and

efficient option for more thorough cleaning and better results,

and should be part of a solid maintenance program.

Understanding Flushing as a Solution

Flushing involves circulating a flushing fluid through a system in order to eliminate contaminants. The dissolved fluid, under high pressure or high velocity, has the ability to dislodge varnish deposits stuck to internal surfaces. Different categories of flushing mechanisms can be used based on system needs and the extent of varnish deposits:

- High Velocity Flushing: It makes use of a flushing fluid with high velocity , which has the potential to lift & dislodge the deposits. It's frequently utilized on vast systems amongst extremes of varnish.

- Chemical flushing: situations where a mechanical flush might not do the job as well as a chemical one, then specialised chemical additives are injected to dissolve the varnish, making it easier to remove.

- Mechanical flushing: This consists of some physical scrubbing or agitation, typically coupled with a flow of associated fluid to break up and flush away the debris.

Flushing not only removes varnish, it also removes other contaminants that degrade equipment.

How Flushing Removes Varnish Deposits

Flushing is somewhat successful at removing varnish because it relies on a mixture of fluid pressure, chemical process, and, in some cases, a form of agitation to reach deposits. Flushing is generally accomplished as follows:

- Preparation: The existing lubricant within the system is drained, and the flushing fluid is added.

- Circulation: The flushing material is circulated at high velocity to dislodge varnish and other deposits from system surfaces.

- Filtration: The fluid is continuously filtered during flushing, filtering out solid particles.

- Inspection: Following the complete flush, the system is inspected to make sure all varnish has been removed and a new lubricant has been installed.

Flushing is a lot more in-depth than wiping is; it tends to get some of the places you simply keep away from with your toilet paper. Also, the flushing can be executed with the disassembly decreased to the minimum so as to eliminate the time and labor.

To know more about how to remove varnish - Click Here

Types of Equipment and Systems That Benefit from Flushing

Varnish can impact all types of industrial systems, and flushing can be used on virtually any machine to ensure the removal of these deposits. Standard applications:

- Hydraulic systems: A buildup of varnish in hydraulic systems can lead to stuck valves, which can hinder system performance and efficiency.

- Turbines: Varnish can disrupt turbine bearings and lubrication paths, negatively impacting performance and increasing the likelihood of failure.

- Compressors: Varnish may clog heat exchange surfaces and reduce precision clearance in compressors, resulting in reduced efficiency or the generation of heat to cause overheating.

Flushing is particularly advantageous in these systems since it can clean system parts in situ without major disassembly, which saves time and money.

Benefits of Flushing for Maintenance and Operations

In terms of varnish removal, flushing has a number of advantages for maintenance teams.

- Enhanced Efficiency: Flushing removes varnish, which can restore the system to working order, allowing components to function as intended.

- Longer Equipment Life: Flushing protects components from varnish build-up, which actually shortens the life of equipment.

- Lower equipment downtime: As flushing is more efficient and faster than manual cleaning, it reduces equipment downtime and enables quick resumption of operations.

- Cost Savings: With less repairs and maintenance, there are considerable cost savings for the organisation.

These make flushing an invaluable weapon in the maintenance teams toolkit to keep high-performance equipment running in challenging environments.

Best Practice Recommendations for Optimal Flushing

There are some best practices to observe in order to have the most successful flush: Keep your mouth clean, sufficient water pressure above your toothed cheeks.

- Choosing the Right Flushing Method: Depending on the foul conditions, select among the high-velocity, chemical, and mechanical flushing.

- Time between flushings: Flushing should be done often enough to prevent varnish buildup to a critical point.

- Safety and Environmental: Use a flushing fluid that is compatible with the system and the environment.

By following these best practices, maintenance crews can ensure that flushing is as effective as possible and that varnish issues are minimized.

Flushing in a Comprehensive Varnish Management Strategy

Though flushing is an effective method, it should be integrated into an overall varnish management program. This strategy might include:

- Regular Monitoring: Routine monitoring through oil analysis can help you find the buildup before it becomes an issue.

- Upgraded Filter Systems: The installation of better quality filters can substantially lower the level of contaminants that lead to varnish buildup.

- Regular Fluid Replacement: New lubricants or high oxidation-stable oils will also help retard the formation of varnish.

By incorporating flushing along with these preventative measures, the process becomes a total concept to varnish control for the ultimate in machinery performance.

Conclusion:

Flushing emerges as a good, dependable and practical option to the

varnish problem in industry. Through proactive varnish removal,

maintenance teams can enhance equipment performance, realise cost

savings and increase the life span of vital assets. In

high-performance equipment industries, investing in scheduled

flushing is an intelligent decision, one that adds to both the

reliability of operation and the bottom line.

As end users place greater emphasis on maintaining equipment life,

flushing will become an increasingly critical element of a

complete varnish reduction strategy.

Learn more about our services and industry insights by visiting our official LinkedIn page: Minimac Systems

FAQS:

- Thermal degradation: Oil breaks down at high temperatures.

- Oxidation: Oil reacts with oxygen to form harmful compounds.

- Impurities: Dirt, water, and metal particles accelerate varnish formation.

- Hydraulic stress: High pressure and turbulence also degrade oil.

- Eliminates contamination: Removes varnish, dirt, and other debris.

- Improves oil flow: Clears blockages for better lubrication.

- Prevents further damage: Reduces wear and tear on equipment.

- Enhances performance: Restores optimal lubrication and cooling.