How Lubricant Quality and Contamination in Lubricant Impacts Bearing Lifespan

Introduction:

Bearing life is influenced by many factors, such as load, speed,

temperature, and lubrication. Bearing problems don’t just mean

expensive repair costs and downtime. By becoming knowledgeable and

taking action on these main “bearings destroyers”, greater life in

your bearings will be achieved with better and smoother operation

and less cost to operate.

Bearings are essential to the smooth operation of numerous industrial machines, from automotive engines to heavy equipment used in manufacturing. To improve the performance of equipment and reduce the costly downtime, it is vital to extend the life of bearing systems by maintaining them effectively, lubricating them properly and monitoring their condition indefinitely. In this detailed guide, we break down the strategies to increase bearing service life and protect your investment in industrial equipment.

Understanding the Life of Bearing

The life of the bearing is defined as the period of (running) time during which the bearing is still able to run on further, without its operation being impaired due to fatigue of the bearing metal or excessive wear. Bearing life is affected by numerous parameters and conditions such as load, velocity, temperature, contamination, etc. Proactive treatment of such conditions results in longer life and higher reliability.

- Load and Speed: Bearing load or speed that is higher than the declared limits of a bearing will increase wear and result in early bearing failure. When loaded to low or zero clearance and operated at high load or speed, the rubbing friction and heat generation are greatly increased, and the bearing material is fatigued.

- Temperature: Excessive temperature deteriorates lubricants, leading to poor lubrication, higher friction, and wear. Effective temperature control is a prerequisite for bearing service.

- Contamination: If dust, dirt, and other foreign substances are allowed to enter the bearing itself, it will cause excessive wear and early failure. Bearing life will be reduced if contamination is not controlled.

The Importance of Lubricant Quality for Bearing Performance

Lubricants help reduce friction, remove heat, and provide separation between moving parts. In the case of bearings, the performance of the lubricant has a direct impact on system efficiency and life. Good lubricants consist of those base oils and additives that provide the following properties:

- Improved resistance to heat: Maintain optimum operating temperature, preventing thermal degradation, which is the leading cause of early bearing failure.

- Better anti-wear characteristics: It helps to prevent friction and wear on bearing surfaces, and the overall improvement in bearing life.

- Oxidation Resistance: Good quality lubricant has relatively higher oxidation resistance, which is important since the oxidative by-products lead to the formation of sludge that can impede the movement of the bearings.

- Protection against corrosion: It adds a protective barrier against corrosion, particularly when exposed to environments with moisture or chemicals.

- Viscosity stability: The viscosity of lubricant dictates its ability to retain a proper oil film between bearing faces. Writing the correct viscosity also means that you are sure that the lubricant will stay where it must stay under different load conditions.

Still not sure how? Connect with our experts: Click here

Types of Lubricants for Bearings

Selecting a suitable lubricant is very important for the life of a bearing. There are different lubricants available, and each offers some unique benefits:

- Mineral Oils: These are the most common lubricants used for bearings. In terms of cost and performance, mineral oils are relatively well placed, but they tend not to last well against the longevity as more specialized lubricants.

- Synthetic Oils: Synthetics are manufactured oils that help withstand extreme environments, like high heat, high-pressure environments, or contamination. Compared to mineral oils, whole synthetic oils protect better and for a longer time.

- Greases: Grease is a blend of oil and thickener, which has many applications in bearings that need to be lubricated for long periods without the need to replace it regularly. The selected grease must be suitable for the operating temperature, load, and speed conditions of the bearing.

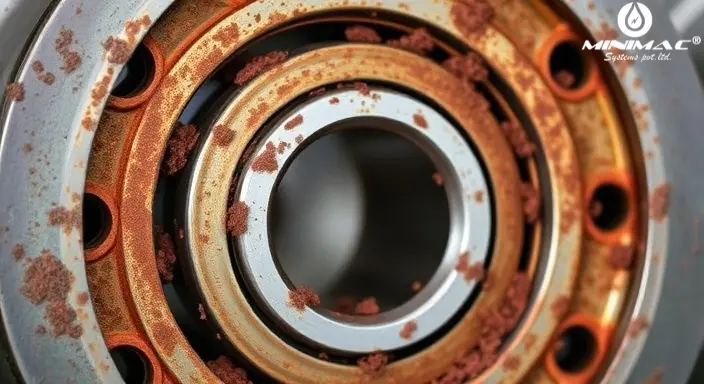

How Contamination Affects Bearing Lifespan

Although lubricant quality is a critical factor, contamination may have a more pronounced effect on bearing performance and service life. Seals, vents, or even during the lubrication process itself can allow contaminants — dirt; water, dust; and metal debris — to enter the bearing. These impurities interfere with its ability to reduce friction and hence, lubricant performance in use, such as:

- Excessive wear: When dirt and abrasive particles get into the oil, it can damage the bearing surfaces. This leads to pitting, scoring, and faster wear.

- Oil Flow Blockage: Debris can block lubrication channels, making the lubricant less effective and inhibiting the lubricant from properly lubricating the bearing.

- Sludge formation: Contaminated water can cause oil breakdown, which creates sludge, harming bearing surfaces and intensifying inefficiencies.

- Corrosion and rust: Moisture or water contamination can eventually lead to rust on the bearing parts, leading to rough operation and a shorter lifespan.

Common Causes of Contamination

The first step to risk management of the contamination in bearings is to learn where the contamination comes from. Some common sources include:

- Environmental factors: Bearings that are used outdoors or in a harsh environment are subjected to exposure to dust, dirt, and water. Those contaminants can readily enter the system and damage the quality of the lubricant.

- Bad sealing: Bearing-out seals that are worn or installed incorrectly will also permit contaminants to enter the lubricant.

- Incorrect lubrication: Excess or insufficient lubricant in the bearing can allow contaminants entry or not protect the components adequately.

- Nearby components may wear: Bearings located in places where other mechanical components have wear may be more susceptible to being contaminated by debris.

How to Prevent Contamination

Contamination prevention is a mix of sealing, cleanup, and filtration. Below are some steps that can help reduce the potential risks of contamination:

- Employ good-quality seals: Invest in seals of good quality that facilitate the bearing to keep under control dirt, water, and other contaminants internally.

- Check lubrication levels: Both the fill of grease or oil must be monitored to prevent contaminants from entering bearing surfaces.

- Filtration systems: Using filtration systems as part of the lubrication circuit helps to eliminate impurities from the oil, keeping your lubricant clean and therefore useful.

- Periodic maintenance: Carrying out periodic maintenance for bearings and connected components can help in detecting wear and tear and keep contamination out of reach of bearings.

How Maintenance Affects the Lifespan of a Bearing

Every bearing could fail if it doesn't get the required maintenance, although bearing failure can be avoided with regular maintenance. Frequent inspection and monitoring help in identifying problems like wrong lubrication, contamination, or wear, way ahead of time.

The Bearings: Key Maintenance Practices

- Lubricant Analysis: Like the oil used in a vehicle, the oil used in industrial machinery requires frequent monitoring of the condition of the lubricant itself, enabling the detection of contamination and depletion events by monitoring the changing characteristics over time rather than waiting until breakdown has occurred. The measurement of lubricant viscosity (viscometer), acid number (acid number tester), and particle count (particle counter) can indicate early symptoms of the problem.

- Inspection of the bearing: checking on a regular basis whether corrosion or other consumption is visible or if contamination occurs, guarantees the bearing is still functioning as it should. These can be visual inspections, vibration analysis, and thermographic imaging.

- Lubricant Replacement: Lubricants degrade over time from heat, oxidation, and contamination. Changing the lubricant on a regular basis ensures that the bearing always receives fresh, high-quality lube.

- Cleaning:Before relubricating, it is important to ensure that the surfaces of the bearings are free from contaminants that can introduce new particles that can damage the bearing surfaces.

- Operating Conditions Verification: By monitoring the machine running temperature, machine pressure, or any other operating condition, the operating verification is super useful to ensure a proper bearing operates within its running parameter limits.

Advanced Maintenance of Bearings

Predictive maintenance measures could additionally extend the

service life of the bearing. Predictive maintenance deploys

sensors and data analytics to keep a live eye on the

well-being of bearings. This provides the opportunity for

interventions to be made in a timely manner, driven by the

knowledge of data, reducing the risk of unplanned downtime and

costly repairs.

Furthermore, condition monitoring systems can monitor

vibration, temperature, and other critical parameters that

affect the health of the bearing. They help safely predict the

possibility of failures so that the operator has ample time to

replace the bearings or lubricant before failure takes place.

Conclusion

Good bearing life and performance rely heavily on the quality

and cleanliness of the lubricant used. By choosing

high-performance, filtered lubrication, ensuring good

lubrication practices, and avoiding contamination, businesses

can severely reduce unscheduled downtime and repairs. In

addition, periodic maintenance and advanced predictive

monitoring often allow early detection of bearing problems,

prolonging bearing life and increasing facility operational

productivity.

Learn more about our services and industry insights by

visiting our official LinkedIn page:

Minimac Systems