Low Oil Pressure: The Hidden Dangers Lurking in Your Machine

Introduction

The oil pressure is a vital aspect of any machinery, whether it is an automobile, industrial machinery, or any machine. It ensures that all the moving components work together in a lubricated environment, thus reducing friction and preventing overheating. But when the oil pressure is sub-optimal, it can cause disastrous results. This article will shine a light on the dark dangers of low oil pressure in your car, and also help you realize how to avoid it by giving you a few tips on what you can do about it before it becomes an expensive repair or even a safety concern.

Understanding Oil Pressure

1. What is Oil Pressure?

Oil pressure is the pressure difference between the oil present in

a machine's lubrication system. It is very important to deliver

oil to all moving surfaces, as it helps to reduce wear and

friction. The oil also draws heat away from the machine, keeping

it cool while running. Low oil pressure can cause these tasks to

go uncompleted, and serious mechanical problems can get the best

of your engine.

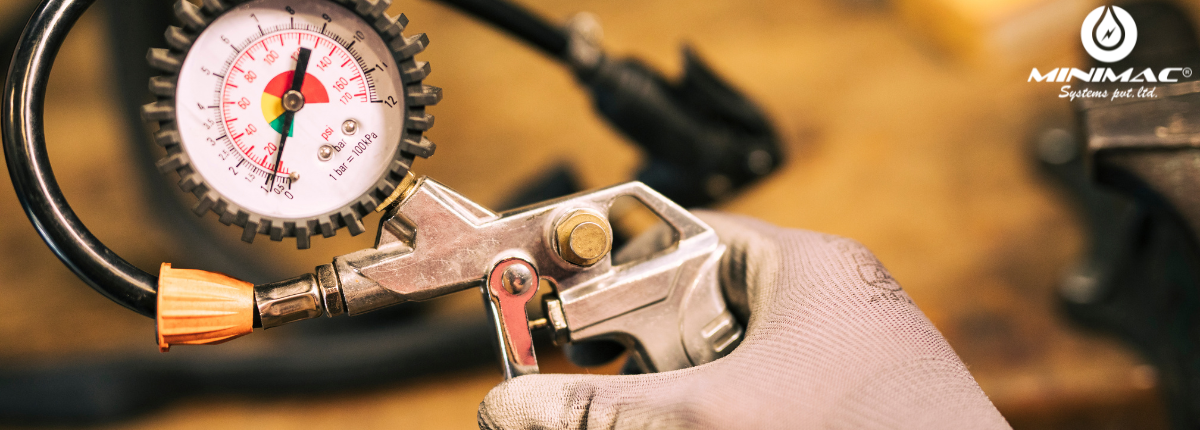

2. Measurement of Oil Pressure

Oil pressure is usually measured by an oil pressure gauge. In

engines, this meter is typically located on an instrument panel

that allows an operator to monitor the moment-by-moment oil

pressure. Normal readings will depend on the type of equipment,

but as a rule of thumb, the oil pressure gauge has whatever the

normal pressure range is listed on its face (about 20- 60psi for

most oil pressure gauges on most automotive/truck engines).

Variations of this norm may suggest possible issues, drawing

attention to these cases.

Causes of Low Oil Pressure

Knowing the most common low oil pressure causes will help avoid the possibility of major engine damage.

A. Insufficient Oil Levels

Perhaps the easiest culprit for low oil pressure is simply not

enough oil. This can happen due to:

Over Time: Over Time: Machines are going to eat up oil eventually,

which is even truer for neglected or older machines.

Leaks:

Oil can sometimes drip at the seals, gaskets, or other areas,

resulting in low levels.

If you have been ignoring your

regular oil checks and changes, the oil may be running low.

3. Oil Pump Failure

The oil pump does the job of delivering oil to different parts of

the machine. If the oil pump is not working as intended, or not

working at all, limited oil flow can occur. Wear and tear, blocked

with impurities, and damage in the internal elements of the pump

are common causes for oil pump failure.

4. Oil Leaks

One common reason for low oil pressure is an oil leak, which can

happen in several different parts of the machine, such as:

Gaskets: The seals that go between different machine parts can

degrade with time, causing leaks.

● Oil Filters: A cracked

or poorly installed filter can cause an oil leak.

● Hoses: A

hose that is either damaged or cracked can cause a loss of oil,

too.

5. Clogged Oil Filters

The purpose of oil filters is to remove harmful contaminants from

the oil to protect the lubrication system. Filters can be caked

with garbage, muck, and grime over time. Low Oil Pressure: A

dirty oil filter can block oil flow and lead to low oil pressure.

Filling the attachment with an eccentric weight can help ensure

that every part of the organization springs also achieves or even

prefers. Player Testimonials Had a bunch of adrenaline rushing

through you in addition the a second. Oil Filter: Also, we help

you save by protecting your investment />

6. Worn Machine Components

Due to the aging of the machines, it is possible that bearing or

piston rings, or seals, get damaged. This can make gaps that let

oil out or decrease system lubrication efficiency, which results

in lower oil pressure. Frequent checks and routine service can

catch worn parts before they ruin your shift or transmission.

For more information about Minimac LVDH - Click Here

Hidden Dangers of Low Oil Pressure

A. Machine Damage

Insufficient oil pressure can cause significant machine damage,

which may include:

● Seized Bearings: Poor lubrication can also cause a bearing

to seize and destroy a machine.

● Scored Cylinder Walls:

Lack of lubrication can lead to metal-to-metal contact and scored

cylinder walls, again, a situation that would require

expensive repair.

B. Increased Wear and Tear

Poor lubrication results in increased friction between the moving

parts, leading to wear and tear. This doesn't just reduce the life

of the parts, it also results in regular breakdowns and expensive

fixes.

C. Overheating

The machine is kept cool by the oil. If the pressure is low, the

oil may not circulate effectively, and in turn, the machine may be

overheated. Excessive heat can warp machinery parts, blow seals,

and even cause machinery to wear out.

D. Reduced Efficiency

There's less efficiency when using machines that have low oil

pressure. They could use extra fuel or power, requiring higher

costs to operate and resulting in lost efficiency. This becomes an

inefficient operation and will be at the expense of

cost-effectiveness.

E. Safety Hazards

Low oil pressure represents real safety risks in an industrial

environment. Machine breakage can cause accidents, injuries , and

even death. Maintaining appropriate oil pressure isn’t just a

matter of maintaining; it’s working safely.

Signs of Low Oil Pressure

A. Dashboard Warning Lights

Today, most machines have warning lights that tell operators if

the oil pressure is too low. Disregarding these messages may

result in machine damage. If you notice this light, you should

immediately check your oil levels and deal with the problem.

B. Unusual Machine Noises

If you hear knocking or grinding sounds from the machine, that’s a

sign of low oil pressure. These noises indicate that metal

components do not seem to have proper lubrication, a condition

that may eventually cause more tear and damage.

C. Performance Issues

If the machine suddenly loses power or stops accelerating, it may

be a low oil pressure warning. If you see these changes, you need

to get your oil pressure and levels checked asap.

How to Address Low Oil Pressure

A. Regular Maintenance

Regular maintenance is key to avoiding low oil pressure. This

includes:

● Frequent Oil Monitoring: Keep the oil level as

recommended.

● Oil Change On Time: The lubrication system

should be maintained as per the manufacturer's intervals.

B. Monitoring Systems

Using monitoring tools that offer real-time oil pressure

measurements can make sure you catch problems before they become

problematic. Lots of the newer machines have those high-tech

monitors already built in, which can signal for help if some

trouble’s a-brewin.

C. Professional Inspections

If you do suspect that there might be low oil pressure in the

engine, it is prudent to seek help from a professional mechanic or

technician. They are able to pinpoint the problem and help you

what to do to get back on the road.

D. Prompt Repairs

Correct any such deficiency without delay. Be it simply adding

oil, changing out that bad pump, or repairing some leaks, “a

stitch in time saves you a fortune” is one of our mantras.

Conclusion

It is very important to understand what low oil pressure means for anyone using machines. With the potential to damage your machine, even pose a safety risk, the consequences are real and expensive. By remaining attentive and aggressive with oil pressure monitoring and maintenance, you can preserve your investment and maintain the efficient operation of your machinery.

Learn more about our services and industry insights by visiting our official LinkedIn page: Minimac Systems