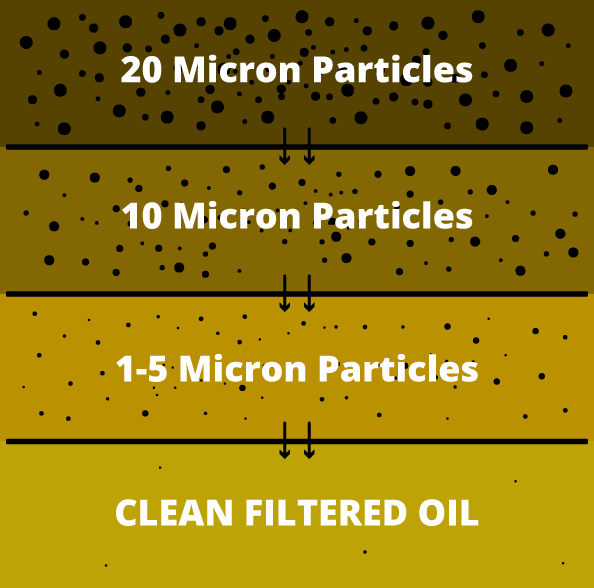

Stage Wise Mechanical Filtration

The first stage is the largest micron rating, i.e. 50 micron or 25 microns. Second stage could be a medium-sized micron rating, maybe 10 or 16 or 20 microns and the final one, polishing filter stage, could be 6, 3 or 1 micron. The decision of micron rating depends on the kind of oil, level of dirt present in the oil and the application where this equipment is used.

Oil Filtration System Lube Oil Flushing System Hydraulic Oil Flushing System Chemical Cleaning System Coalescer Separator SystemLow Vacuum Dehydration

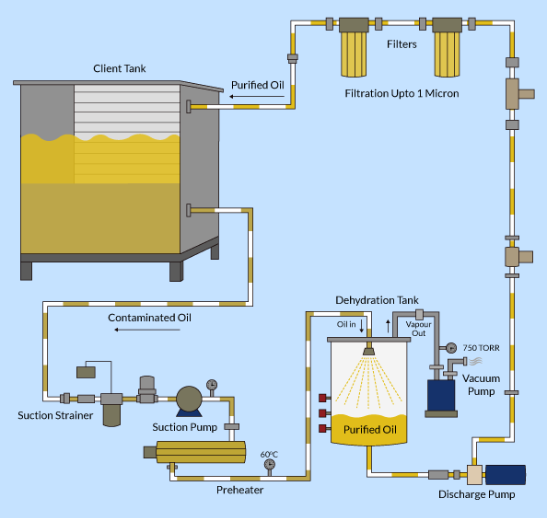

This technique is used for removal of moisture content from the oil, which is present in three forms:

- Dissolved

- Emulsified

- Free form

The technology evolves around the fact that water boiling point is 100℃, when the vapour pressure above the water surface is atmospheric pressure. But when we reduce the vapour pressure to a vacuum condition say 750 torr, it's evident that the boiling point of water reduces from 100℃ to 60℃.

Oil Dehydration System Transformer Oil Filtration SystemElectrostatic Fluid Cleaning

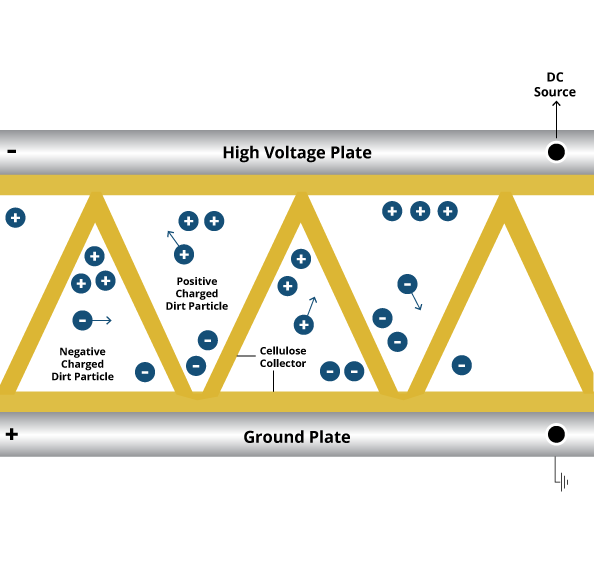

This calls for electrostatically charged electrodes inside a water bath.

It is a known fact that all foreign particles carry some charge. While we create positive and negative electrodes on the oil bath, the foreign particles which are negatively charged would be attracted towards the positive charged electrode and vice-versa. Thereby, after some interval of oil passage the particles would be attracted towards the respective oppositely charged electrode and a separation of particles happen.

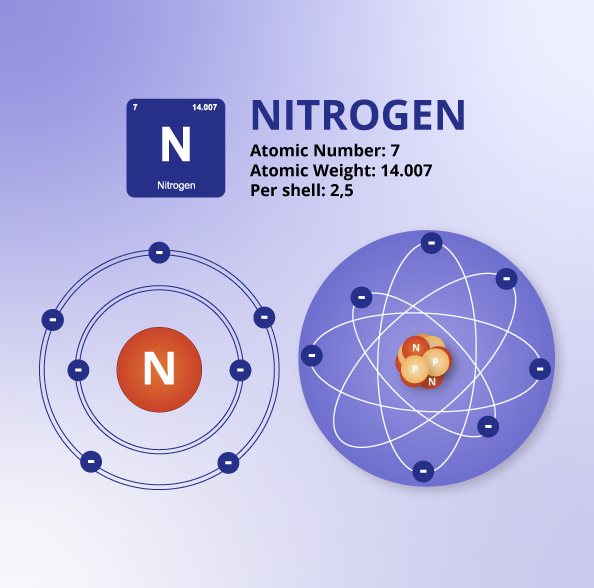

Electrostatic Lube CleanerNitrogen Blanketing

This technique talks about the creation of an inert gas blanket in the header space of oil tanks.It has been seen that the header space of oil tanks, especially in the coastal areas, is full of humid air. This humidity is the biggest concern for oil oxidation and degradation. Hence, dry inert gas blanketing technology enables us to create a dry environment in the header space of these tanks. Having an inert gas ensures absence of oxygen, which would be the key element for oxidation and oil degradation.This technique has enabled a number of governing systems, lube oil systems in the coastal regions and they help them to reduce the problems of oil oxidation and degradation.

FRF Conditioning SystemTan Reduction By Ion Exchange

This is a technology which is used for reduction of TAN (Total Acid Number) value in the oil. TAN value is an indication of total acidity formed in the oil, which leads to an understanding of oil degradation.If we analyze the oil chemistry, there would be an understanding that oil degrades and forms carbonic acids and carboxylic acid groups. These lead to a condition where the oil is no more lubricating and it loses its basic properties. Hence, it is very important to maintain the TAN value within manufacturer subscribed limits.

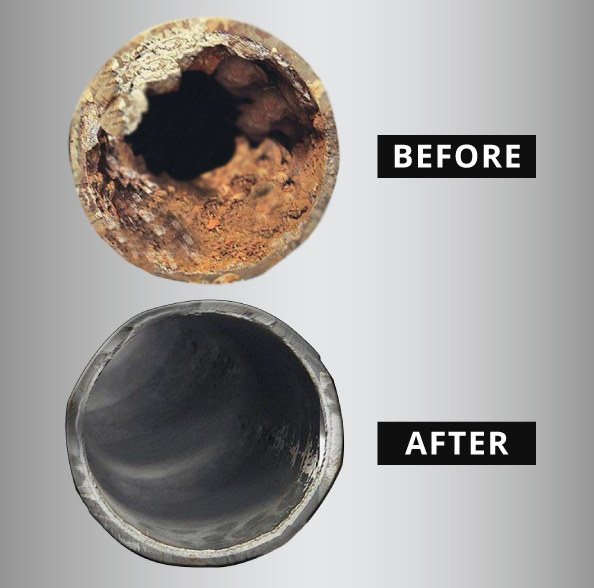

FRF Conditioning SystemHigh Velocity Flushing

This is a technique to clean pipelines, cavities, internals of the components.

The technology does not stop only for application on lube oil, but can be extended for chemical cleaning, water glycol flushing, water flushing and hydraulic oil flushing. The key element for right product offering depends on the requirement of the client and the diameter of the pipeline as well as the fluid which has to be used for flushing.

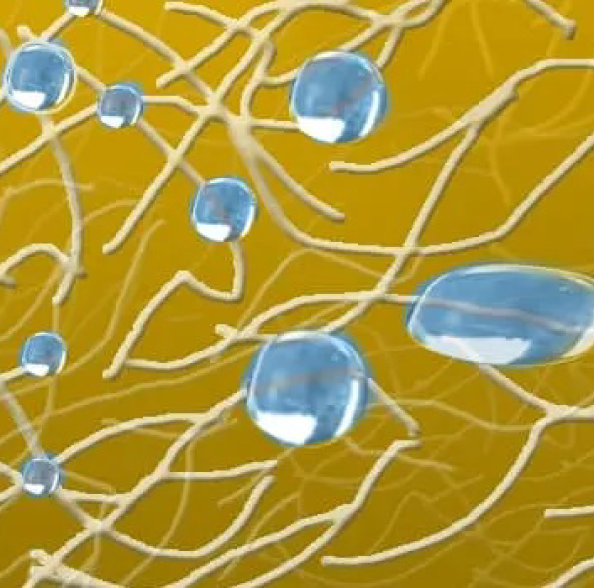

Lube Oil Flushing System Hydraulic Oil Flushing System Chemical Cleaning SystemLiquid - Liquid Coalescing

A technique used to separate vapors, liquids, soluble particles, or oil from some other fluid through a coalescing effect. The coalescing effect is the coming together of liquid aerosols to form a larger whole, which is easier to filter out of the system due to increased weight. Phase separation of liquids using specific gravities.

Coalescer Separator SystemOnline Particle Analyser

Contamination is a major cause of mechanical element failure. Wear and tear can be detected by monitoring contaminants' shape and composition. To identify and track the source of contaminants, a Particle Analyzer is essential. It counts particles and categorizes contamination levels based on particle size.

The Particle Analyzer is a crucial test in oil analysis, detecting a wide range of problems. It measures particle quantity and size in an oil sample. It has various uses, such as testing filter leaks, assessing real-time cleanliness and filter efficiency, and establishing testing routines.