WHAT ARE BYPASS FILTERS?

A bypass filter/pressure relief valve is a vital component of an oil filter. The valve opens when the oil is too thick or the filter is blocked. The filter is going to blow up at some point if that valve does not open.

They are used for the removal of very fine organic and inorganic particles and belong to the category of bypass filters. This further boosts the aggregate size of oil consumed. So, if you have a contamination problem and are looking for operating equipment life extension, lube oil & service intervals extension, also consider bypass filters. Now we can say that bypass filtration can also be treated as a cost and downtime-saving factor.

Most of the current ones are ‘full-flow’ oil filters; they protect the component by preventing large particles from reaching it, but cannot filter out soot, water and silt. Oil cannot be kept clean indefinitely by full-flow filters alone. Bypass filters can get rid of those fine particles that compose most of the contamination.

Now, before purchasing any bypass filter, it is recommended to do the homework. Here are just a few things to keep in mind:

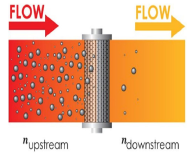

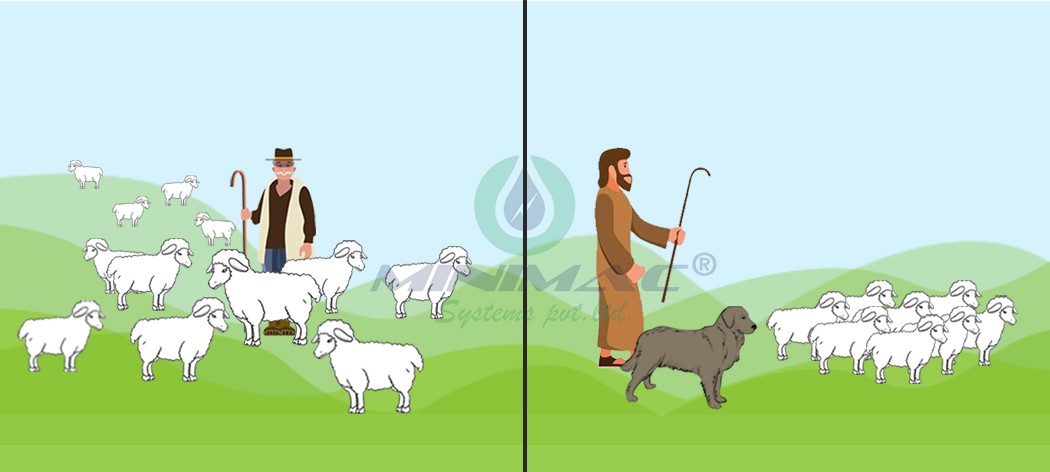

- Capture efficiency - The Better the beta ratio, the better the capture efficiency. Choosing an appropriate value of beta ratio can restrict how the particles leave the element, just like an efficient shepherd controlling a sheep ensemble in the field.

- Pressure/flow - The Filter element, designed appropriately, has a predetermined flow and oil velocity through its microvoids. Just as you want to keep the stream water flowing in a controlled manner for gardening reasons. Otherwise, it will ruin the purpose of watering.

- Dirt Holding Capacity - Just mere high capture efficiency is not sufficient; a good filter element capacity to hold the collected contamination is a critical factor! An engineered element has space to lock up the undesired pollutants.

- Heating element (for solid and liquid contaminants Removal) - Increased temperature causes the solid impurities to get removed and helps to accelerate the speed of the elimination of flammable/volatile impurities.

- Filter media: - change widely with grade and oil type. This can be a qualitative filter paper to an absolute and depth filter media.

- Fluid Compatibility: Not all filter elements are compatible with any oil grade. Even a tiny error in choosing the element could result in eliminating the element or potentially leading the entire system to collapse.

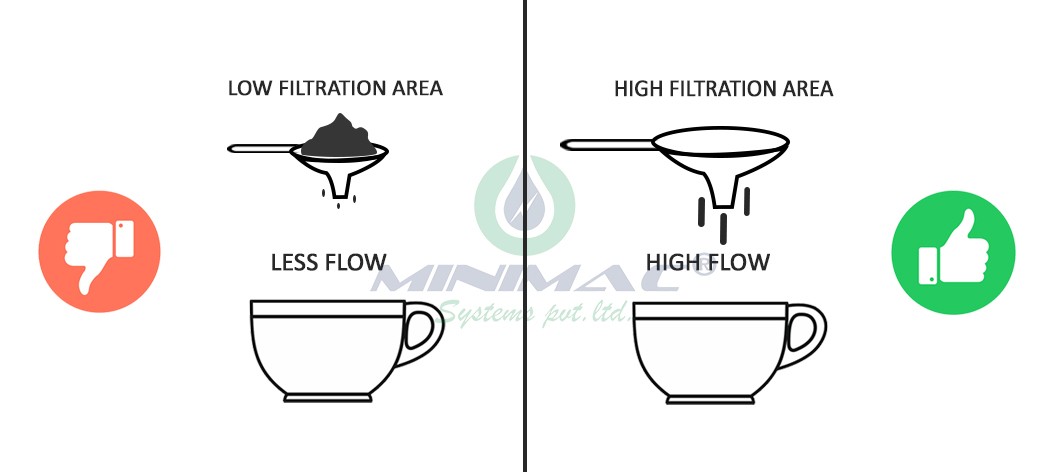

- Filtration surface area: The more surface area, the lower the pressure drop across the filter and the greater the flow rate.

- Space saving: Size reduction with respect to the filter elements and housing provides us several advantages like space & cost-saving, aesthetically pleasing appearance, lesser maintainability, lower recurring expenditure, etc.

- Cost-effective to implement and install: At the end of every engineering and calculation, there is economics involved. However, to address the financial constraints, opting for an optimized design and accurate sizing is always recommended.

For more such interesting Articles and Case Studies: Click Here

There is no need to have any extra settings for securing a Bypass filtration system; it operates in the zone of the trained limits. When a bypass filtration system is correctly designed, installed, and maintained, it can make a significant contribution to preventing contamination ingress into the system following the filtration phase of the process.

We would be more than happy to assist you throughout the right filter selection process. Get in touch - enquiry@minimac.in or reach out to us on WhatsApp at +91 89560 09769.

Learn more about our services and industry insights by visiting our official YouTube channel.