Best Practices for Hydraulic System Maintenance

Introduction:

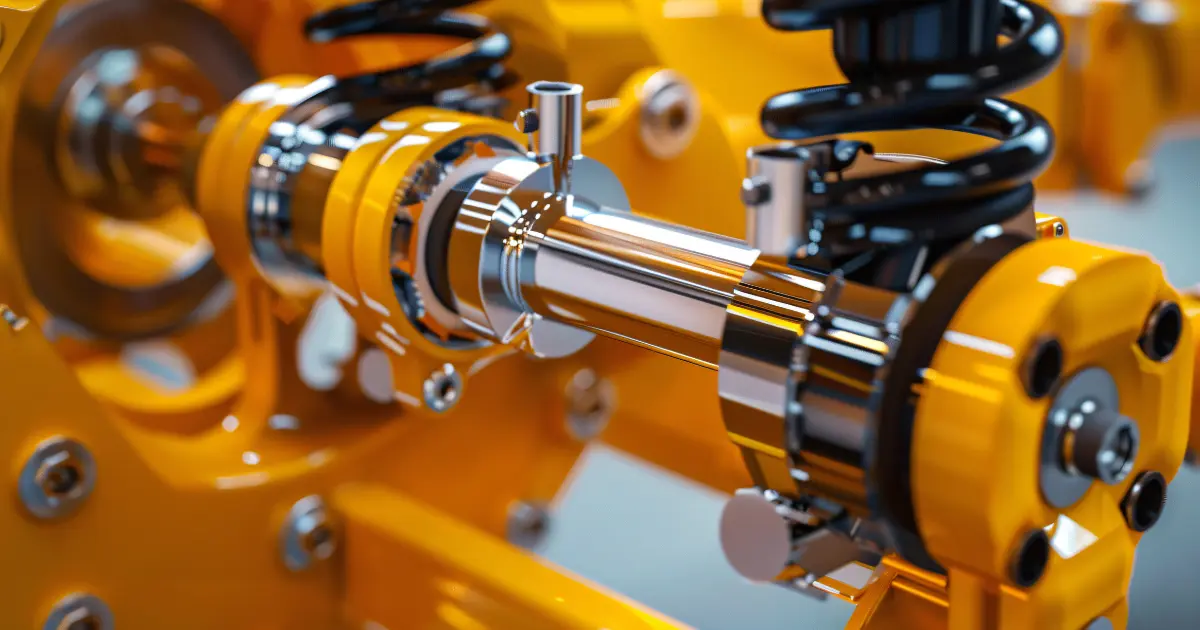

Hydraulic systems are the forgotten heroes behind countless industrial operations. From cranes and excavators to injection moulding machines and presses. But without consistent maintenance, even the strongest hydraulic setup can grind to a halt. The biggest culprit? Contaminated or neglected hydraulic fluid. Keeping your hydraulic oil clean is definitely a smart move. It helps avoid breakdowns, extend component life, and maintain efficiency in demanding applications.

Below are some of the best practices to ensure your hydraulic system stays in peak condition, whether you're managing a high-pressure press or a forklift on the shop floor:

Why Clean Oil Matters

Oil plays a number of major functions in hydraulic systems, which power equipment in manufacturing, construction, and other sectors. It transmits energy from the pump to cylinders and motors, lubricates moving parts, carries heat away from working components and seals clearances to prevent pressure loss. When the fluid becomes dirty or deteriorated, it can no longer do its job efficiently. Contaminants introduced during assembly and external dirt or wear particles increase stress on components and decrease equipment life. Preventive hydraulic system maintenance is not only a crucial step in keeping machines reliable and minimising costly downtime, but also one of the best practices out there.

Hydraulic Oil's Many Jobs

To understand why maintenance matters, it helps to appreciate what hydraulic oil does. Hydraulic oil is a single fluid that brings together power transmission, lubrication, heat transfer and sealing. As a medium for energy transmission, pressurised oil allows heavy machinery to move and respond at precise points. The same oil lubricates valves, pumps and actuators, reducing friction and preventing early component failure. It also absorbs heat generated during operation and transfers it to coolers so that the system doesn't overheat. Finally, hydraulic oil seals clear the spaces between moving parts to limit leaks and maintain pressure. Because one fluid performs all these functions, maintaining its cleanliness is essential.

Where Contamination Comes From

Contamination has many sources. They can enter the system during assembly if internal surfaces aren't thoroughly cleaned. Dust and humidity in the environment can infiltrate through breather caps or worn seals. During operation, ingress through faulty seals or open ports allows particles and moisture to enter. Contamination is also generated inside the system as components wear or fluids degrade. Hard particles that rub component surfaces cause abrasive wear, while fluid voids that collapse cause exfoliation, which erodes metal. Fatigue, erosive and adhesive wear break down components further. Corrosive wear, often triggered by chemical contamination or water, produces rust and degrades surfaces. Particles lodged in hydraulic valves compromise machine control and increase abrasive wear. Built‑in contaminants from manufacturing can dramatically raise warranty costs, which is why equipment manufacturers set contamination limits, verify compliance and flush assembled systems before use.

The Damage Dirty Oil Does

Once contaminants circulate, the consequences can be serious. Abrasive particles scratch component surfaces, degrade seals and cause internal leakage, forcing pumps and motors to work harder and consume more power. Corrosive wear from water or chemical contaminants produces rust and pitting. When valves stick due to debris, machine control suffers. If contaminants aren't controlled, minor wear can cascade into serious breakdowns that halt production and require expensive repairs.

Spotting Water Problems

Water contamination is a hidden danger. Dissolved water is invisible and held in solution until the oil reaches its saturation point. Once saturated, any additional water may form emulsions or separate as free water, creating a milky or cloudy appearance. Highly refined mineral oils with few additives can hold only about 100 parts per million of dissolved water at 70°F, while ester‑based hydraulic fluids used in rolling mills may hold more than 3,000 ppm before reaching saturation. Oversaturated fluids appear cloudy and can lead to corrosion, reduced lubricity and cavitation damage. Identifying water contamination early by looking for cloudiness, measuring saturation levels or performing water content tests helps prevent these issues.

Decode ISO 4406

Because particles are invisible to the naked eye, the industry uses numeric codes to assess fluid cleanliness. ISO 4406:1999 is the reporting standard for hydraulic and lubricating fluids. The code consists of three numbers that correspond to the number of particles larger than 4, 6 and 14 microns per millilitre of fluid. For example, A code like 19/17/14 shows the number of particles in a millilitre of fluid, with the first number for particles 4 microns or larger, the second for 6 microns or larger, and the third for 14 microns or larger. However, the code should be considered one data point among many; raw particle count data and trend analysis are needed to determine whether a system is becoming cleaner or dirtier over time. ISO 4406 codes apply to fluids and should not be used to specify cleanliness limits for individual components; large particles can cause severe damage during initial startup.

Hitting Your Cleanliness Target

How clean is clean enough? It is far less expensive to keep contaminants out than to remove them. It may cost ten times more to remove a gram of dirt than to prevent that gram from entering the oil. Determining a required cleanliness level involves balancing the cost of contamination control with the risk of downtime. Calculating the required cleanliness level (RCL) considers factors such as working pressure, duty cycle, component sensitivity and environmental conditions. A high‑performance servo valve, for instance, will require a cleaner fluid than a hydraulic cylinder because it has tighter clearances and is more sensitive to contaminants. In general, the higher the system pressure and the more sensitive the components, the lower the ISO code you should target. Setting a realistic cleanliness goal, measuring against it and adjusting maintenance practices accordingly is the cornerstone of fluid power maintenance.

For More Information About Hydraulic Systems - Click Here.

Keep Contaminants Out

Keeping contaminants out starts with the basics. Minimac recommends always using the correct grade and quality of hydraulic oil for your equipment. Monitor seals and replace them before they fail to prevent dirt and moisture ingress. Install proper filters and maintain them; modern filtration technology can remove particles as small as 3 microns, significantly extending equipment life. Regularly check oil condition by looking at cleanliness, viscosity and colour and change the oil when necessary. Flush the system thoroughly before filling with fresh oil. Avoid opening the system unnecessarily and protect entry points with clean caps and breathers. These small steps form the foundation of preventive maintenance for hydraulics and greatly reduce the likelihood of contamination.

Filter It Right

Filtration isn't just about having a filter but about choosing the right one and maintaining it. Advanced filtration systems can remove particles down to 3 microns without damaging the oil. Using filters with the correct micron rating for your system and changing them at prescribed intervals ensures that abrasive particles don't build up. Flushing assembled systems to achieve a roll‑off cleanliness target before starting up helps prevent built‑in contaminants from circulating. For case drains and other lines where contaminants accumulate, small dedicated filters can capture debris and prevent it from recirculating.

Flush Like a Pro

Filtration alone cannot remove sludge and varnish that build up in lines and valves. That's where hydraulic oil flushing comes in. Flushing removes contaminants, wear particles and degraded oil to keep systems operating smoothly. Regular flushing prevents equipment failures because it removes debris that would otherwise wear components. It improves performance and response times by restoring proper flow and pressure. Flushing extends oil life by removing impurities, reduces the risk of sudden failures and maintains safety by keeping hydraulic pressure stable.

A successful flush starts with using suitable quality oil and checking its viscosity and particle count before and after flushing. Follow the manufacturer's recommended flushing intervals and procedures, and inspect system components for wear before and after the flush. The practical method includes shutting down the system, draining old oil into a proper container, connecting flushing equipment, pumping flushing oil through the system, and replacing filters. Once flushing is complete, fill the system with fresh oil to the correct level and test for leaks and pressure.

Flushing isn't a one‑size‑fits‑all procedure. Chemical cleaning uses solvents to dissolve varnish and sludge, but must be handled carefully. Mechanical cleaning uses filters and special apparatus to extract particles directly. Ultrasonic cleaning employs high‑frequency waves to dislodge contaminants from hard‑to‑reach areas. Choose the method that suits your system's design and condition. As for timing, flush as part of routine scheduled maintenance, when oil shows signs of pollution or discolouration, when performance drops (e.g., slower response or unusual noises), or when you must change the oil frequently. Minimac's guide emphasises keeping the flushing area clean, following the service manual, draining old oil properly, connecting hoses securely, monitoring flow and pressure during flushing, replacing filters and refilling with the correct oil. For complex systems, professional flushing services can save time and ensure that industry standards are met.

Inspect & Troubleshoot

Maintenance doesn't stop after flushing or filtration. A simple inspection checklist helps catch issues early and aids hydraulic system troubleshooting. We suggest looking for changes in oil colour or odour, higher operating temperatures, unexpected system behaviour or visible particles in the oil. Any of these signs may indicate contamination or impending failure. Routine oil analysis determines contamination levels and guides corrective actions. In addition to checking the oil, inspect hoses and fittings for leaks, ensure rods and cylinders are clean and undamaged, verify that all filters and breathers are intact and look for unusual vibrations or noises. Document findings in an inspection log; this information helps technicians troubleshoot when performance issues arise.

Built‑in Dirt & How to Beat It

Even new components can bring contaminants into a system. To avoid this risk, hydraulic equipment manufacturers establish contamination limits for components and verify that parts meet those limits. They then flush assembled systems to achieve a roll‑off cleanliness target before shipping. As a maintenance professional, you should take similar steps: flush new systems before putting them into service, use clean assembly practices, keep components capped until installation, and never assume that a new hose or valve is clean. By controlling built-in dirt, you reduce the initial contaminant load and make it easier to maintain cleanliness over the system's life.

Conclusion

Hydraulic system maintenance may sound complex, but it ultimately comes down to a simple principle: keep the oil clean! Hydraulic fluid performs multiple functions, and any contamination compromises those roles. Contaminants come from many sources, like assembly debris, environmental dirt, wear particles and water. Dirty oil increases stress, energy consumption and downtime. Following ISO 4406 cleanliness codes and setting realistic targets helps you measure progress. Practical practices like using high‑quality oil, maintaining seals, filtering effectively and flushing regularly prevent contamination. Monitoring water content, performing routine inspections and analysing oil samples allow early detection. Finally, recognising that it is cheaper to keep dirt out than to remove it and that built‑in contamination must be managed will save money and extend equipment life. By embracing these best practices, lay operators and technical experts alike can relax knowing that their hydraulic systems stay dependable, working and safe.

Learn more about our services and industry insights by visiting our official LinkedIn page: Minimac Systems