Lubricating Oils: Essential Guide to Oil Sampling and Analysis

Introduction:

Oil is critical in mechanical systems, helping to provide a protective barrier to lower friction, heat, and wear between mechanical parts. This paper focuses on the importance of drawing appropriate samples and the method of analysis, all with the aim of the healthy assessment of machinery.

The Role of Lubricating Oils

Lubricating Oil, the Lifeblood of Your Equipment Lubricating oils are the “lifeblood” of every engine and machine. These key roles include:

1. Friction Control: Lubricating oils provide a layer between contacting surfaces to reduce friction between them to a minimum. This reduction in friction increases efficiency, as well as the life of the mechanical part, by reducing the wear and tear that occurs during normal operation.

2. Control wear: When you reduce friction, lubricants minimize the wear of parts that would otherwise have been worn from contact with each other direct contact, so the machine could still function without any problems over a long period of time.

3. Prevent Corrosion: Lubricating oil film is capable of isolating and protecting the contact metal surfaces from moisture, impurities, and chemicals. Such prevention of corrosion is necessary to keep the mechanical operation of the machines longer in the long term.

4. Cooler temperature: Oils do not generate heat from mechanical operations. Lubricants also prevent overheating, which can cause system failure and performance loss, by keeping operating temperatures within safe limits.

5. Prevent Contamination: Lubricants are ideal when it comes to eliminating loose dirt, debris, and other contaminants within machinery. This process keeps the system clean and ensures that it is able to operate smoothly and efficiently.

6. Power Transmission: The oil energy plays an indispensable role in power transmission between components, such as hydraulic machinery, to achieve efficient energy transformation and utilization.

7. Motion Control: They are also used to control the motion of parts to enable free movement while preventing jamming or component failure, especially when machinery is accurate and finely calibrated.

The Necessity of Oil Sampling

Regular oil sampling is key for successful maintenance plans. It gives an indication of the state of the lubricant and the machine it lubricates. Incorrect sampling methods, however, can produce inaccurate results and cause the equipment to break down prematurely.

Really Looking After Your Oil: The Sample is Key

1. Turbulence:

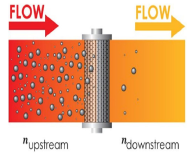

- Ideal Sampling Locations: The best place to take samples is in oil flow turbulence, i.e., sharp bends in or elbows of piping. These sites are likely to be more contaminated than sites with laminar flow, facilitating the risk of false negatives, or at least deceptively clean samples.

2. Ingress Points:

- 2.2 Sampling point downstream from the area of wear. It is also recommended that a sample be taken on the return to the main tank. This prevents a contaminated fluid from being diluted by mixture with clean fluid of the downstream clean oil.

3. Filtration Considerations:

- Filter In Samples: Always sample 'upstream' of any filters. Downstream samples will likely look better because of the filtration that hides the real amount of contamination.

Methods of Oil Sampling

Precision oil sampling involves a number of techniques:

- Pressure Line Sampling: During this procedure, sampling is performed on pressure lines upstream of filters. It guarantees that an operating sample is representative.

- Drop Tube: However, the drop tube method can also be used on non-pressurized systems to draw from the sump or the reservoir by means of a drop tube to the oil.

- Sampler with Vacuum Pump: A Vacuum pump is ideal for sample collection in multiple systems without any risk of contamination from outside.

Understanding Oil Analysis

After samples are obtained, they are analyzed to establish their condition. Examined key components examined are as follows:

- Viscosity: Indicates the oil’s resistance to flow; necessary for proper lubrication under conditions of fluctuating temperature.

- Contaminants: Detections of particles from wear and contaminants relevant to machine status.

- Additive Usage: Indicates if necessary additives in the oil have been depleted or broken down with use.

- Water: Measures water in the oil and water can cause corrosion, reduce lubrication, and create sludge.

- Acid Levels (TAN - Total Acid Number): Indicates the acidity of the oil to determine if the oil is oxidized or contaminated, as this will cause corrosion and reduce the life of the oil.

For More Information About Oil Analysis - Click Here.

Decisions Being Made Using: The Oil Analysis Guidelines for Oil Condition

Oil changes should be according to oil condition, not at specified intervals (such as time or hours). This has potential for cost savings and enhanced machine reliability. A precise Oil Analysis Report will help make informed decisions on when to perform maintenance via a maintenance schedule or even identify needed repairs.

Types of Contamination and Their Impact

You must familiarize what substances to avoid.

- Particle debris: Created as part of normal operation; may indicate wear on components.

- Water Contamination: Can cause emulsification and corrosion if left unchecked.

- Fuel Dilution: This can occur in the engine and can greatly change some lubricant properties.

Conclusion

The effectiveness of lubrication management via adequate techniques of sampling and analysis is of critical importance in machinery health. Through learning how to obtain representative oil samples and make reliable interpretations of analysis reports, operators can improve equipment reliability and extend equipment life while reducing operating costs.

The #knowyouroil series by Minimac Systems is aimed towards the intelligence of the user of these key areas that will keep their machines fit and smart enough to battle any bad oil!

In conclusion, a lubricating oil is a critical component in a machine’s working system. Correct sampling techniques are vital to meaningful analysis and informed maintenance scheduling that will yield less downtime and increased productivity in mechanical operations.

Keep your machine oiled and running great – have an oil checkup done today by our trained technician!

Learn more about our services and industry insights by visiting our official LinkedIn page: Minimac Systems