Hot Oil Flushing: A Complete Guide to Hydraulic and Lubrication System Reliability

Introduction

In modern industries, system failures can lead to massive losses. One invisible yet powerful cause of such failures is contamination. That’s where hot oil flushing comes into play — a high-efficiency maintenance procedure that ensures your hydraulic and lubrication systems stay clean, reliable, and high-performing. Let’s dive into everything you need to know about hot oil flushing — how it works, when to use it, its benefits, and why it’s essential in heavy industries.

What is Hot Oil Flushing?

Hot oil flushing is a critical process used to clean hydraulic and lube oil piping systems. It involves the high-velocity circulation of heated oil to remove internal contaminants. These contaminants include debris, dust, welding slag, mill scale, varnish, and oxidation by-products that accumulate inside the pipes and system components. The goal is simple — achieve required ISO cleanliness levels before the system is commissioned or re-commissioned. The process mimics real operational conditions, allowing you to dislodge and remove the most stubborn impurities, especially those clinging to pipe walls and component surfaces.

Why Is Hot Oil Flushing Important?

Contamination is the silent killer of hydraulic and lubrication systems. Particles as small as 4 microns can cause severe wear to precision components. If not removed, contaminants can lead to:

- Early equipment failure

- Increased downtime

- Reduced oil life

- Higher maintenance costs

Hot oil flushing not only cleans the system but also prevents these outcomes, ensuring reliable and efficient machinery performance.

How Does Hot Oil Flushing Work?

The process begins by connecting a flushing skid to the system. This skid includes a high-capacity heater, pump, and multi-stage filtration unit.

Here’s a typical flow:

- System Setup – Temporary hoses and filters are installed.

- Oil Heating – Oil is heated between 60°C to 80°C to reduce its viscosity.

- High-Velocity Circulation – The oil flows through the system at turbulent speeds, usually Reynolds number >4000.

- Particle Dislodging – Turbulent flow loosens debris stuck to internal surfaces.

- Filtration – Dislodged particles are captured in inline filters.

- Monitoring – Particle counters measure the cleanliness level.

- Completion – Process continues until the target ISO 4406 cleanliness level is achieved.

When Should You Perform Hot Oil Flushing?

Timing is critical. Here are the most common scenarios:

- New System Commissioning: Remove welding debris, rust, and construction residue.

- Major Repairs or Overhauls: Clean out old oil and contaminants.

- Post-Fabrication: Eliminate mill scale and grease from manufacturing.

- Before First Oil Fill: Avoid mixing flushing debris with new oil.

- During Preventive Maintenance: Extend system life and avoid downtime.

Ignoring these intervals can compromise the system's reliability and reduce overall efficiency.

Industries That Rely on Hot Oil Flushing

Several industries rely on hot oil flushing due to their high precision and reliability requirements:

- Power Generation: Turbines and generators must remain contaminant-free.

- Oil & Gas: Hydraulic systems on rigs and refineries need clean operation.

- Petrochemical: Valves and compressors are sensitive to solid particles.

- Steel Plants: Continuous production demands clean lube and hydraulic lines.

- Marine: Flushing ensures trouble-free performance of propulsion and deck systems.

- Aerospace and Defense: Precision systems demand ultra-clean oil conditions.

In these sectors, contamination can mean catastrophic failure.

Learn more about our Hydraulic oil flushing system

Top Benefits of Hot Oil Flushing

- 1. Increased Equipment Lifespan: A clean system experiences less friction and wear. Components last longer, reducing replacement frequency.

- 2. Enhanced Efficiency: Hot oil flushing removes blockages and varnish that reduce flow and pressure. This ensures optimal performance.

- 3. Reduced Downtime: Fewer failures mean less unscheduled maintenance. That translates into higher productivity and savings.

- 4. ISO Cleanliness Compliance: Meet or exceed cleanliness standards like ISO 4406. This is critical for warranty validation and OEM recommendations.

- 5. Oil Life Extension: Removing sludge and varnish prevents oil degradation. This keeps your lubricant functional longer.

- 6. Safer Operations: Clean systems respond faster and more accurately to commands. This reduces the risk of accidents.

Best Practices for Effective Hot Oil Flushing

For successful flushing, follow these expert recommendations:

- Use the Right Oil: Always flush with oil of the same base stock as operational oil.

- Maintain Ideal Temperature: 60–80°C helps loosen varnish and reduce viscosity.

- Ensure Turbulent Flow: Low flow rates won’t dislodge particles.

- Install Inline Filters: Filters must capture particles before recirculation.

- Track Cleanliness Levels: Use particle counters to monitor progress.

- Change Filters Frequently: Don't wait for high-pressure drops; change filters proactively.

Skipping these steps can lead to ineffective flushing and system failure.

Signs Your System Needs Hot Oil Flushing

- Cloudy, dark, or sludgy oil

- Unusual noises or vibrations

- Sluggish system response

- Repeated component failure

- Increased operating temperatures

- Sticky valves or actuator delays

- Appearance of varnish or sludge deposits

If any of these symptoms appear, your system is overdue for flushing.

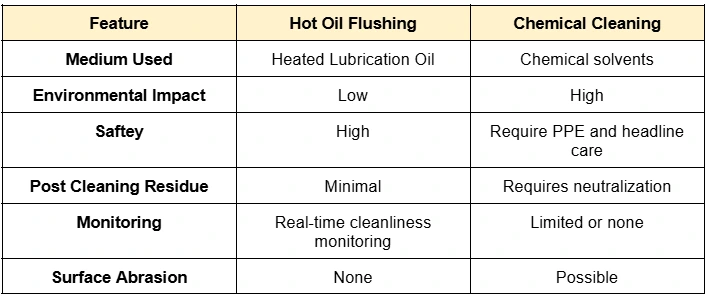

Hot Oil Flushing vs. Chemical Cleaning

While both methods are used for cleaning, they serve different purposes. Hot oil flushing uses heated oil and high flow rates to remove contaminants safely, with minimal residue. Chemical cleaning uses solvents, requires neutralization, and poses higher environmental and safety risks. Hot oil flushing is preferred for live systems.

How to Choose the Right Flushing Partner

Not all service providers deliver the same quality. When choosing a vendor, ensure they:

- Use ISO-certified equipment and methods

- Provide cleanliness certification post-flushing

- Have experience in your specific industry

- Offer trained engineers and on-site monitoring

- Use state-of-the-art filtration systems

A reliable partner can save your business from unexpected breakdowns and ensure long-term efficiency.

Conclusion

Hot oil flushing is not an option — it's a necessity. Clean oil is the lifeblood of every hydraulic and lubrication system. Whether you're commissioning new machinery or maintaining legacy equipment, flushing protects your investment. Every hour of downtime is lost revenue. Every contaminated drop of oil is a potential risk.

Learn more about our services and industry insights by visiting

our official LinkedIn page:

Minimac Systems

Stay clean. Stay productive. Stay ahead.