What Is Varnish And Its Effects

Oil health translates to system health in terms of lubrication and hydraulic system condition. Two things are indispensable to guarantee productivity, to prevent malfunctions, and to keep operating costs down:

- Keeping an eye on the state of the fluid

- Operating equipment needs continuous maintenance

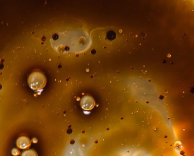

Varnish is a chemotype cluster of soluble and insoluble contaminants consisting of oil decomposition and oxidation byproducts. It can manifest itself as a gel-resin-like consistency, or look like a solid precipitate in the oil, or whether the metal surfaces of lube systems are coated with it. It can also result from multiple potential root causes such as ambient temperature, ESD, lubricant breakdown, and micro-diesel. It's varnish that can cause a host of machine operating issues like valve stiction, lubricant flow obstruction, and dirty filters, among others.

What is varnish, and put simply, how does it differ from sludge?

Varnish is a troublesome, sticky oxide or carbon material that settles on inner code surfaces of a machine. Varnish often cures to a hard/brittle consistency with hot surfaces and/or time.

Sludge, which is often used as a precursor to varnish, on the other hand, is soft, sticky, and mobile, whereby it will travel around the system, eventually settling out at sump bottoms, troughs, strainers, filters, and narrow fluid passages.

What are some of the leading contributors to varnish within your system?

In short, here are the main causes of varnish:

- Thermal degradation under pressure.

- Pressure-induced dieseling

- Oxidation

Is your system susceptible?

Several factors contribute to high rates of varnish contamination in lube oils. You should test your oil for varnish potential if your system does any of the following:

For Call for oil check +91 89560 09769

For More Information Click Here

- Presence of deposits or staining of lube circuit members

- If you changed from group I to group II oil, or have blended oils

- Tiny lube oil tank with rapidity of lube oil

- High operating temperature

- A gas turbine, gas compressor, or hydraulic drive system

How to establish a physical basis for change in composition.

Here are the warning signs of the oil being changed chemically:

- Change in oil colour

- Strong odour

- Change in oil consistency

- Slush and tough deposits on metallic surfaces

- Oil samples with visible oil contamination

In case of varnish deposits, there are two suggested actions to control it. So , the first step is to identify the root causes. It is going to mandate some sort of methodical investigation into the contributors, backed by the oil evaluation. From there, use it to get rid of whatever varnish is already present in the machine.

We provide flushing and filter check services like they do at Minimac Systems, where the entire system , from the oil tanks to the lines themselves, is cleaned. Schedule a Consultation with Our Technical Expert today By Visiting the Website https://www.linkedin.com/company/minimacsystemsprivatetlimited Or Call At: +91 89560 09769

Help to spread awareness and sensitize the reader for Zero Mechanical Breakdown, Like, Comment, Share this article.