What’s the Circular Economy in Lubrication?

Introduction

By 2070, many nations, including India, are aiming to achieve net-zero emissions. In India, Niti Aayog has launched 11 committees for encouraging Circular Economy concepts in 11 specific areas. Businesses can make noticeable progress towards reaching their net-zero goals with the support of lubricant life cycle decarbonisation.

The lubrication industry means the blood of rotary and hydraulic equipment. The condition of lubricants directly influences the working capacity, continuous operation, and durability of the machinery. Equipment leaks, unexpected shutdowns, and routine replacements are the main causes of used oil lubricants. Different grades of lubricants that are gathered in tanks, which are not segregated, are usually disposed of, burnt, and sold to waste oil collection services without any way to track their final use. In contrast to the corporate ESG objectives, these practices are thought to be linear and increase the danger of uncontrolled GHG emissions into the environment.

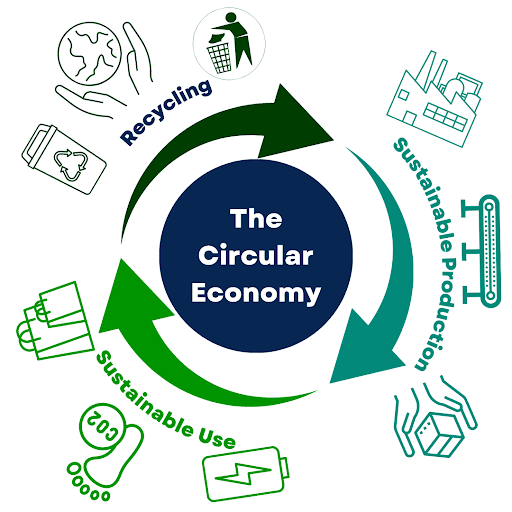

The Circular Economy in Three Steps

We need to shift from this linear strategy to a circular economy to bring down the steady rise in GHG emissions. To understand the carbon footprint of lubricants and how to decarbonise the lubricant life cycle, it is necessary to first grasp a few terms such as Gradle to Gate, Cradle to Grave, Nano, Micro, and Macro Circularity. Cradle to Gate describes how the lubricant is made and distributed. Direct or indirect routes can be used to deliver oil to customers' gates. The term "cradle to grave" refers to the complete life cycle of lubricants, from production to disposal. It covers raw material extraction, distribution, use, and end-of-life oil treatment. Organisations may reduce their carbon footprint and support a circular economy instead of a linear economy by promoting this approach. The circular method incorporates three important procedures that prolong the practical lifespan of materials:

(Oil Treatment in Midlife) Nano Circularity

This step entails using reconditioning solutions to treat oil mid-life. As a result, fewer fresh oil purchases are made, the drain interval is extended, part failures are decreased, and productivity rises.Some studies point out that, there is a 2.5% reduction in GHG emissions for every 1% increase in energy efficiency. This idea promotes the ideas of "Reform" and "Reduce." It also supports oil condition monitoring for longer lubricant reliability.

(End-of-life Treatment) Micro Circularity

Oil treatment with additional reconditioning solutions is part of this step. As an in-service lubricant approaches the end of its useful life, the oil needs to be gathered and graded in spent oil storage tanks. After reformation, the used oil retains its oil qualities and may be utilised again in lubricated machinery. By reconditioning, the lubricant may be brought back to its original form and made suitable for use in the lubricated machinery. The whole amount of oil utilised is no longer converted into hazardous waste. This move advances the lubrication industry's future through lubricant reuse.

Macro Circularity

This phase stands for the collection and industrial oil recycling of waste oil. Annually, billions of gallons of industrial lubricant are disposed of in landfills, incinerators, or, worse, leak into the environment. Only 15% go through oil re-refining process. The gathering and waste oil management of unharmed waste oil is the final step in greening the lubrication industry. After recycling the waste oil, the refiners produce re-refined base oil, or RRBO, which lubricant makers utilise as feedstock. This method encourages "Recycle" and aligns with waste oil disposal norms.

For More Information About How Minimac Helps ESG - Click Here.

A couple of systemic adjustments that prioritise sourcing, logistics, optimal use, and disposal are also prerequisites to the success of this circular model:

- Sustainable lubrication Sourcing and Production: Industries may reduce the present 2:1 production-to-waste-oil ratio to 1:1 by implementing energy-efficient, IIoT-enabled, and sustainable production methods, including bio-based lubricants.

- Improving Lubricant Usage: This is vital to reducing the quantity of greenhouse gas emissions. It may be achieved by mid-life oil treatment, appropriate lube management, and trustworthy lubrication training and education.

- Proper Distribution and Supply Chain: Using renewable energy sources and concentrating on methodical logistics also significantly lowers the carbon footprint during transit.

- End-life management: The production of high-quality, more economical, and productive re-refined base oil (refined base oil). The circular model cannot be realised without the establishment of well-organised used oil recycling facilities and appropriate disposal.

Conclusion

In conclusion, decarbonising the lubricant life cycle may not get much attention, but it might result in major financial and environmental benefits. Industries can cut waste, minimise emissions, and get closer to their net-zero goals by re-engineering the production, usage, and recovery of lubricants. Lubricants should no longer be viewed as a throwaway consumable but rather as a resource that should be used to its fullest potential and handled with care.

Learn more about our services and industry insights by visiting our official LinkedIn page: Minimac Systems.