Steam turbine oil analysis practices

Introduction:

The Global market analysis on ‘Turbine oil‘ provides such regional data with the help of a positioning of the market participants, in addition to their financial position analysis. The published market studies are designed to provide readers with a detailed understanding of the regional market position and the risk of losing money in one or more regions. The market study “Turbine oil“ forecasts the global turbine oil market to grow at a CAGR of 3.498% during the period 2017-2021, and the market size has the potential to grow by 1500.05 K MT during 2020-2024. Its momentum will accelerate during the forecast period. The Manufacturers of Turbine oils are in constant collaboration with OEMs in order to supply high-performing turbine oils to cater to the increasing requirements of the global market. These days, our industries are more concerned with making the lubricant, as well as the equipment, last, and a Reliability lubrication Program is a great way to help achieve that goal. In this piece, we attempted to provide as much turbine oil information as we could so the power generation and manufacturing sectors could take a step closer moving forward with a sustainable, cost-effective solution.

Turbine & its lubrication system:

Utilization of the available thermal energy in high-pressure steam is made by the heart of the power plant: the turbine, which is a solar receiver and converts it into mechanical energy on a rotating output shaft. This mechanical energy is employed to spin the rotating equipment, crush, and to move air or gases (fan, blower, pump, compressor), and to spin a generator for the creation of electric power.

Now with these steps, let's know a summary of the oil flow of the turbine, and then the main component and what the function of the component is in the lubrication of the turbine.

- The oil system consists of an oil tank (heated for starting)

- Adequate oil pumps for the required oil pressure

- Oil coolers to remove operational heat from the oil

- An oil filter to collect eroded debris from the circulating oil

- Pressure control valve to adjust a precise and consistent supply of oil pressure to the bearings

- Furthermore, one pressure relief valve to each pump (commonly of rotary type) has been installed to protect from overpressure

- An accumulator is for reducing surging pressure when there is an operating change, such as an exchange from the main machine to the spare machine.

- A Temperature Control Valve (TCV) allows coolers to be bypassed during cold oil conditions to provide proper oil viscosity and good lubrication. Sometimes this is accomplished by regulating the flow of water in oil coolers.

Importance of turbine oil:

Living in this accelerated world, where electricity is one of the most crucial components of our life and a single day without it could debilitate our pace of life, productivity, and hamper the global economy as a whole, then electricity generation is critical to us no matter what. To cater to this progressive demand, power plants are working with a fine attention to detail to enhance their performance and reliability. In power generation, the most important machine is the Turbine, which acts as a mechanical driver for all rotating equipment’s leading to the generation of electric power. The reliability and availability of the turbine are extremely reliant on the turbine oil, and thereby, lubricant selection is an essential part of the reliability program. But the turbine OEM takes great care of defining the properties of the lubricants, laboratory tests of oil analysis, and typical references for the best performance of the turbine.

Turbine oil has to face a hostile environment, such as fluctuating temperatures, heavy load, contamination, moisture, entrained air, heat, and several physical & chemical transformations. Critical functions of oil include lubrication of bearings & journals, flushing debris from rotating components, sealing gases from entering, hydrostatic lifting of shafts, metering valves during the hydraulic cycle, and protecting lube-system insides.

The current state of the art in lubrication technology demonstrates the significant advances that have been made in the design of turbine oil. Base Oil is 90-95% of turbine oil, the rest percentage is additives like antioxidants, rust inhibitors, antiwear additives, antifoam agents, demulsifier, metal deactivators, and pour depressants.

To learn more, visit: www. www.minimacsystems. Com

Turbine oil properties, types, and brands:

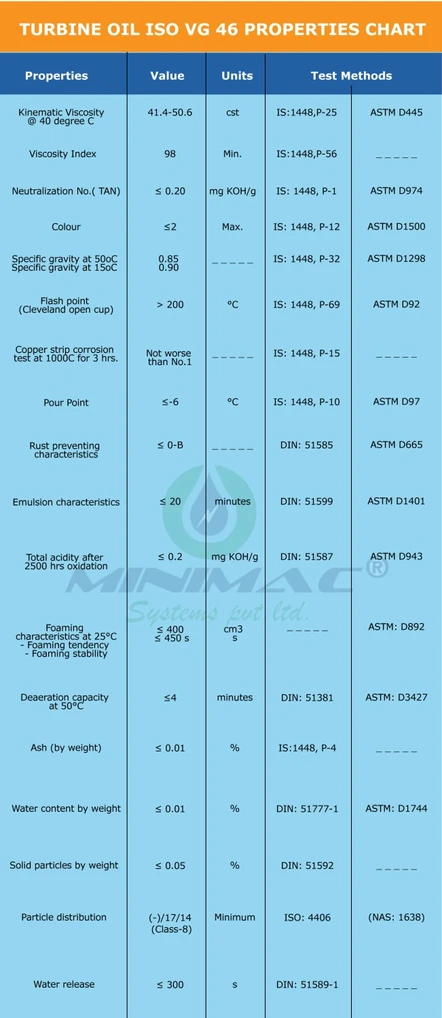

Steam turbine oil characteristic features are to Provide uniform lubrication performance over wide range of ambient and operating temperatures, Control Emulsification Properties, minimize the deposit of Varnish, Sludge, Emulsion & entrained gas/foam, Prevent Rust, Minimize Acid attack in copper alloys, enhances lubricity, minimize Oxidation, good oil degradation solubility, improves filtration, etc. The oil that satisfies the properties mentioned above is ISO VG 46.

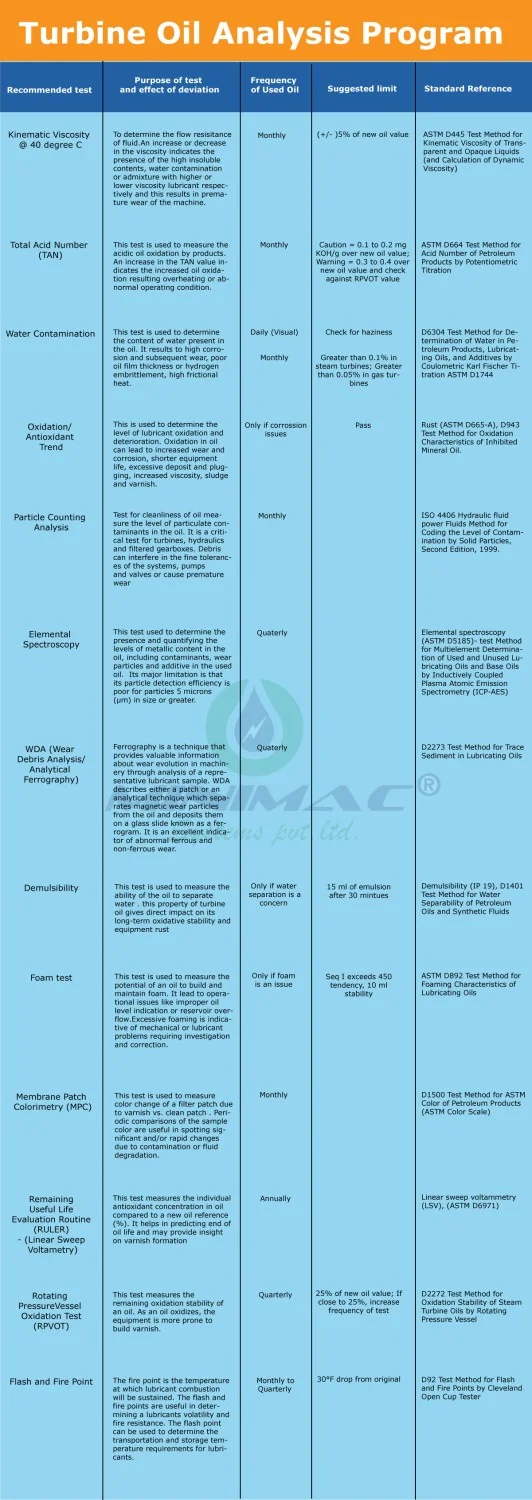

The following chart aggregates the total estates as well as the recommended concentration, and how to analyze each one:

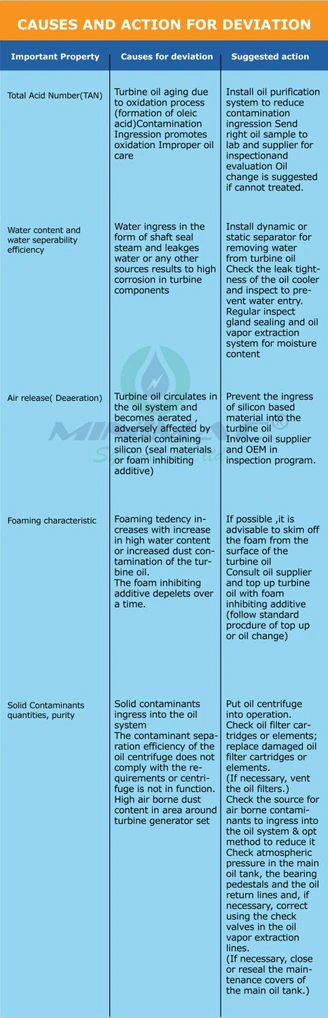

While turbine oil is formulated for a long life, operating in severe conditions will alter the oil properties. Here we will consider the reasons for the deviations for a few key properties and what can be done:

At Minimac, we understand your maintenance needs and offer the best solution. We believe in Discern, Design & Deliver.

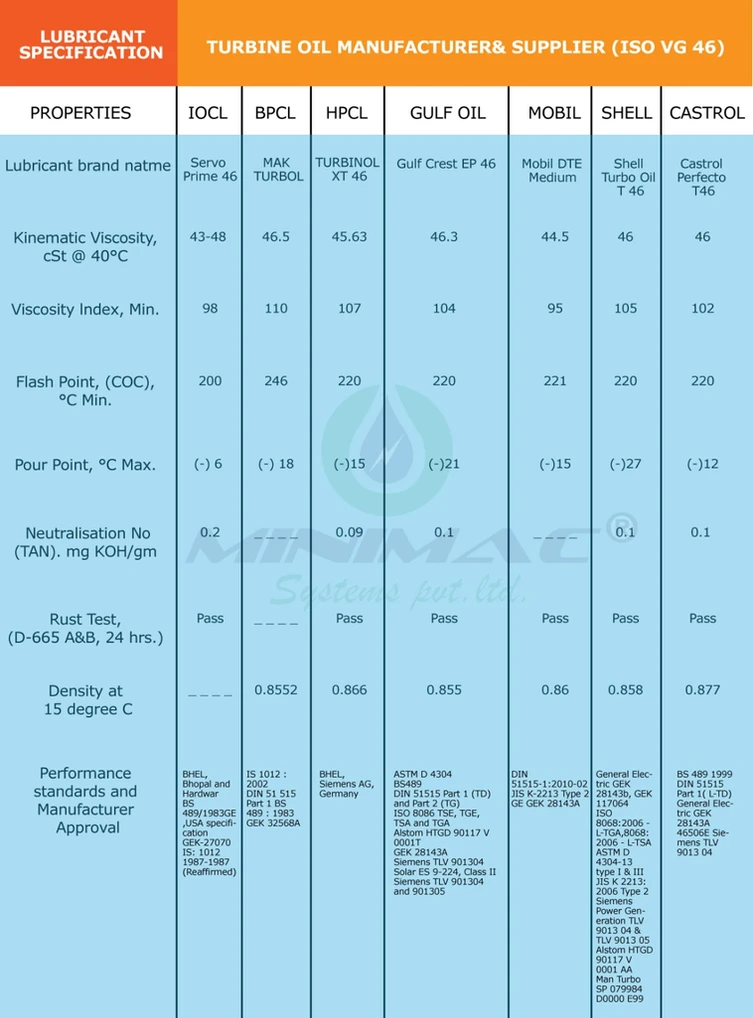

Lubricant Supplier Sourcing and brands:

Finding an appropriate supplier that can meet the performance requirement for the turbine is one of the of a reliability-based lubrication program. There are many things to be considered while finalizing the vendors, like; Quality of the Lubricant & Services, Technological Advancement, Trouble Shooting support, Emergency support capabilities, Technical Support, Laboratory Support, Price & Delivery potential.

Top suppliers of turbine oil in India and across the world are IOCL, BPCL, HPCL, Gulf Oil, Mobil, Castrol, Shell, Chevron, Valvoline, to name a few. done by the manufacturer: Properties Relevance to the Performance of Turbine Oils of the performance of turbine oils.

Turbine oil maintenance (sampling points, testing standards, testing scheduled)

Sampling points:

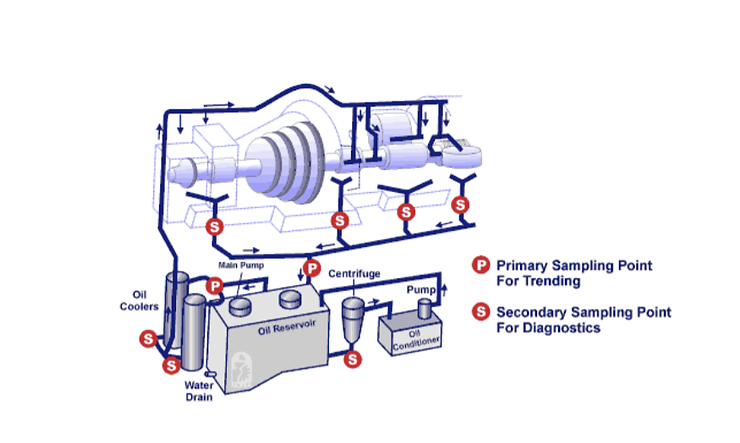

- Optimize the density of information about oil data

- Reduce Deterioration of Information

- Primary Points: Sampling point (return line or drain valve, elbow, any turbulent area). Secondary Points: Anywhere in the system to isolate an upstream component

- Proper frequency

- Proper sampling hardware

- Sample when the engine is up to normal operating temperature

- Take a sample once a flow of little oil passes through the sampling point, 0.5- 1.0 L.

- Use clean, dry sampling equipment that is dedicated to the sampling of used oils.

- The samples need to be analyzed in the laboratory or tested on-field within 24 hours after the overmction.

- The sample bottle must be filled up to 90% and sealed well to eliminate the possibility of leakage during transportation to the laboratory.

The figures below indicate the primary and secondary sampling points of the turbine lube oil system as follows:

Primary Sampling Point: The location at which a regular, scheduled oil sampling program is conducted to monitor and trend wear metals, oil condition, and oil contamination.

Secondary Sampling Position: Diagnostics and troubleshooting in each component, wear metal debris and oil contamination measurements.

Testing Standards:

Power Plant lubrication monitoring is broadly specified under ASTM D4378 and ASTM D6224, and these define almost every test used to qualify lubricants for new and in-service monitoring for power plants. The following are major standards and OEM approval standards

- ASTM D4378, "Standard Practice for In-Service Monitoring of Mineral Turbine Oils for Steam, Gas, and Combined Cycle Turbines"

- ASTM D6224, "Standard Practice for In-Service Monitoring of Lubricating Oil for Auxiliary Power Plant Equipment", focuses on auxiliary equipment that supports power-generating turbines.

- FED-STD-791D (testing method of lubricants, liquid fuels, and related products)

- Ahlstom - Gas and Steam - HTGD901117

- GE - Gas - GEK 32568f

- GE - Steam - GEK 46506D

- Solar - ES9-224

- MHI - Steam & Gas - MS04-MA- CL001 and CL002

- Siemens/ Westinghouse - K-8962-11

Testing schedule with standard reference:

Watch our Low Vacuum Dehydration System video: Click here

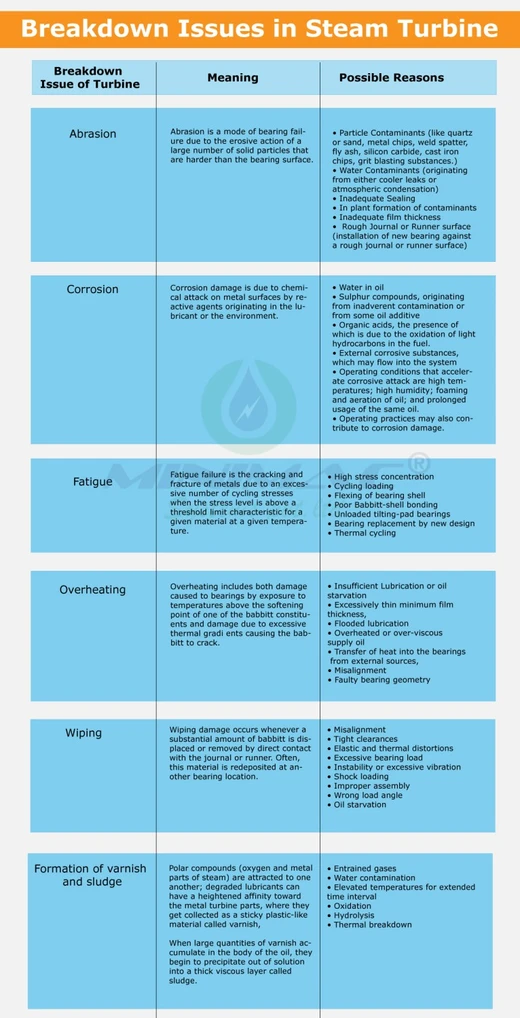

Steam turbine breakdown problems:

1. Bearing Failure

Bearing & Journal problems are a leading cause of turbine

generator downtime. Although poor design or workmanship may be to

blame on occasion, the single most common reason for these

problems is incorrect operating conditions. A turbine trip has a

strong possibility of happening when bearing/shaft vibration hits

the trip set point. Major reasons for rapid wear & tear & failure

of the Turbine Generator Bearings in operations:

- Improper Lubrication (Inadequate: incorrect flow, dirty oil, wrong oil temperature)

- Excessive load (i.e., force pushing the shaft against the bearing)

- long periods of operation with high vibratory levels, and this can lead to fatigue cracks in the bearing lining.

- Insufficient oil flow and pressure cause wiping off of the babbitt material

These operating conditions can lead, for example, to either bearing overheating, bearing scuffing, or to wear of bearing surfaces by contaminants of oil or to fatigue.

2. Blade Failure

“Any power player will have nightmares about a turbine blade failure. Another problem is that frequently occurring and common operational issues are contributing to one another. These include deposits, erosion, corrosion and vibration, fatigue, and manufacturing defects. The principal modes of blade failure are stress corrosion cracking and fatigue cracking as a result of too high a level of blade vibration.

Failure of the blade can result in catastrophic damage to the turbine. At worst, one or several of the long-moving blades of the LP turbine would rupture the casing and itself become the turbine missiles. In less serious instances, the broken blade (which obstructs the movement of its other blades) shears or bends others. The resultant excessively high vibration can cause rubbing of the turbine generator bearings, seals, oil lines, etc. 9 Such of case occurred in 2014 at a large power generation facility in India at a 600 MW LP turbine, the last-stage blade broke at the lacing wire area and damaged 5 more blades. It resulted in a unit outage of over 90 days!

The damaging effects of such breakdowns, the identification of causes of bearing failure, and the most effective means of repair are of critical importance. Sublevel *A very common myth with the lubrication system is that “keeping filters in line with oil circuits will prevent failures due to contamination”. It is the paradox of the crisis when filters and obstructions in the system are all bypassed by an emergency oil supply, in order to reduce the demands, and the failure comes out of the emergency system. (From the fact that DC pumps commenced and failed from the oil's deleterious effects).

*Another filter myth is that “all the filters are created equal”. The filter is a deep well, and it’s not just putting some filter media in a can. Its uses were: from selection of the media, it is a long way, such as sizing filters, pressure drop, dirt holding capacity, burst pressure, fugitive particles, etc. So, it is always recommended to choose a trusted seller.

If turbine bearing failure wasn't just a matter of bearing replacement cost and time wasted, and damage done to the rotor. There was one Chinese-supplied machine of 300 MW in India, which suffered from oil starvation during a blackout in 2017 and damaged the rotor, which led to a loss of billions of rupees in revenue for the company.

Consolidated turbine oil care and maintenance points:

In addition to oil analysis, the following lubrication practices should be observed to ensure optimum performance of the Steam Turbine:

- Keep oil clean, cool, and dry

- Examine the bulk delivery of new oil before acceptance

- Maintain proper alignment

- Perform regular oil analysis

- Fit high-capture-efficiency breathers

- Examine for foaming and/or air entrainment

- Fit primary and secondary sampling points

- Periodically check (and preferably daily) the sight glasses for level, foam, and water

- Maintain dry headspace in the tank headspace using blowers, condensers, or instrument air

- Precision contamination control: Use off-line fluid conditioning.

- Check for varnish frequently in gas turbines

- Analyze the oil periodically

- Record the temperature and the duration of the use

- Its inlets are equipped with filters and strainers to keep solid contaminants in the tank.

- Also, install a versatile oil cleaning device in order to avoid solid and flexible contaminants

- Inspect oil filter cartridges or elements periodically

- When inspected, the main oil tank and the bearing pedestal, together with the oil cooler, must be emptied of turbine oil.

- Reuse the oil only after all the parameters are within normal test limits

- Any small vibration change must always be taken up as the first priority

- Keep a watchful eye on your condition monitoring results and perform the test again should these results deviate from the norm.

Call +91 89560 09769 for Mechanical Maintenance & Oil Check.

About the Author: Ms. Preeti Prasad is associated as Technical Consultant and Business Development Manager with Minimac System Pvt Ltd. She is a chemical engineer with work experience in Oil Refinery and also provides lubrication consultancy services to many companies/sectors. She holds Level I Machine Lubrication Technician(MLT) certification through the International Council for Machinery Lubrication (ICML).

Reference Taken:

- Machinery Lubrication India- Noria Corporation Ltd

- Monitoring and Optimizing Life of Turbine Oil by Analyst, Inc

- Troubleshooting bearing and lube oil system problems by Thomas H. McCloseky

- BHEL documents on Stem Turbine Maintenance and Turbine Oil Care Maintenance

- Turbine Operational Problem (module 234-14)

- PDS of the mentioned oil manufacturer